Spiral Bevel Gear Cutting Machine

Machinelist: Spiral Bevel Gear Cutting Machine

Spiral Bevel Gear Cutting Machine

- Leyendecker & Hollmann GmbH

- Giesenheide 18

- 40724 Hilden

- Deutschland

-

+49 (2103) 28097-0

+49 (2103) 28097-99 -

info@LHmachine.com

www.LHmachine.com

#1083-03108 · Spiral Bevel Gear Cutting Machine

KLINGELNBERG - C 28 P - - 2002 - Sinumerik 840C

Technical details

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-18018 · Spiral Bevel Gear Cutting Machine

KLINGELNBERG - C 28 P - - 2002 - 840 C Siemens

Technical details

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17298 · Spiral Bevel Gear Cutting Machine

KLINGELNBERG - C 28 P - - 2002 - SINUMERIK 840 C

Technical details

Internal deburring device U axis / Q spindle chip conveyor coolant device Electrostatic air purifier ELBARON no tools No workpiece clamping device

Datasheet

Request / Contact

- MW-MACHINES

- Dorf 9

- 4133 Hofkirchen

- Österreich

-

+43 (0)66718068977

- -

info@machines-mw.at

machines-mw.at

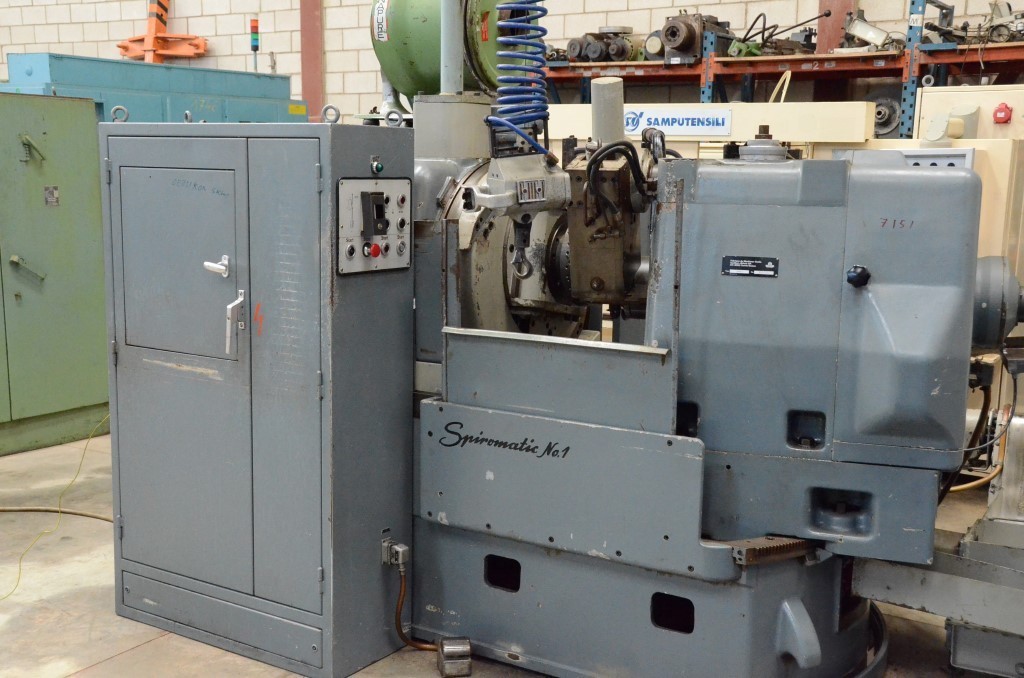

#2077-90037 · Spiral Bevel Gear Cutting Machine

OERLIKON - SKM 1 - - -

Technical details

Tooth width max. 50 mm Adjustment range for hypoid wheels (offset) +/- 60 mm. Through hole for spindle pieces 78 mm. Plunge max 20 mm. Feed rates for cutting, infinitely variable 0.04 - 25 mm/min. Distance taper tip/workpiece spindle... 100 - 345 mm. Distance taper centre/knife head axis 25 - 150 mm. Distance taper centre/milling head spindle... 80 - 220 mm. Max. disc wheel Ø with medium spiral angle... 320 mm. Max. Gear ratio 1 : 9.5 Module 2.1 - 7.5 Outer bevel distance approx. 170 mm. Rapid traverse 1.5 m/min. Roller feeds in minutes from angle pe... 0,3 - 20 Spindle nose with short taper, inside 140 mm. Spindle nose with short taper, outside 85 mm. Spindle speeds in standardised steps 40-250 rpm. Rotation around the machine centre axis 90º Ø max. gearbox 320 mm. Ø of spindle nose 130 mm Electrical properties Motor cooling capacity 1.2 Cv. Main motor power 10 Cv. Motor power chip conveyor 0.3 HP. Forward motor power 2 HP. Hydraulic motor power 2 HP. Total power 13 Kw. Voltage 220/380V.

TOP Manufacturer:

KLINGELNBERG - OERLIKON -