Gear cutting machines

Machinelist: Gear cutting machines

Autom. Rack Milling Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23252 · Autom. Rack Milling Machine

KNAPP-DONAU - UZFM 300 H - - 1964 -

Technical details

Accessories: Change gears Milling arbors Operating instructions

Datasheet

Request / Contact

Bevel Gear Generator - Spiral

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24006 · Bevel Gear Generator - Spiral

HURTH-MODUL - KF 250 B - - 1998 - Siemens Sinumerik 840 C

Technical details

incl. suction

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-16040 · Bevel Gear Generator - Spiral

KLINGELNBERG - KNC 25 P - - 1997 -

Technical details

max. wheel diameter mm gear width mm max. module 6 min. module 1.5 max. workpiece diameter 275 mm tooth width max. 5.5 mm spiral angle 0 - 60 ° number of teeth 5 - 120 transmission ratio min. 1:1 transmission ratio max. 1:10 milling drive motor 20 kW workpiece drive 14.5 kW total power requirement 62 kVA weight of the machine ca. 12 t dimensions of the machine ca. 4,7 x 4,387 x 2,45 m Tool spindle (D-axis) - workpiece spindle speed (infinitely) 60 to 350 [...] Tool positioning axis (E-axis) - swivel range 0 to 360° - swivel speed max. 19.5°/s Workpiece spindle (B-axis) - mounting diameter outer cone (1: 4) 140 mm - standard internal cone (1:20) 99.218 mm - workpiece spindle speed max. 300 [...] - workpiece spindle passage 90 mm Workpiece positioning axis (Y-axis) - travel 870 mm - speed max. 4.5 m/min Roller rotation axis (A-axis) - swivel range 315° - swivel speed max. 40°/s Axis intersection (Z-axis) - travel range max. +/- 50 mm - speed max. 0.657 m/min Workpiece swivel axis (C-axis) - swivel range -8.5 to 98° - swivel speed max. 21.5 °/s Milling depth axis (X-axis) - travel from -25 to 640 mm - max. speed 6 m/min Machinen distance (V-axis) - travel 150 mm - speed max. 1.6 m/min

Datasheet

Request / Contact

- Leyendecker & Hollmann GmbH

- Giesenheide 18

- 40724 Hilden

- Deutschland

-

+49 (2103) 28097-0

+49 (2103) 28097-99 -

info@LHmachine.com

www.LHmachine.com

#1083-02478 · Bevel Gear Generator - Spiral

KLINGELNBERG - KNC 25 P - - 1997 -

Technical details

Tool spindle (D-axis) - workpiece spindle speed (infinitely) 60 to 350 r.p.m. Tool positioning axis (E-axis) - swivel range 0 to 360° - swivel speed max. 19.5°/s Workpiece spindle (B-axis) - mounting diameter outer cone (1: 4) 140 mm - standard internal cone (1:20) 99.218 mm - workpiece spindle speed max. 300 r.p.m. - workpiece spindle passage 90 mm Workpiece positioning axis (Y-axis) - travel 870 mm - speed max. 4.5 m/min Roller rotation axis (A-axis) - swivel range 315° - swivel speed max. 40°/s Axis intersection (Z-axis) - travel range max. +/- 50 mm - speed max. 0.657 m/min Workpiece swivel axis (C-axis) - swivel range -8.5 to 98° - swivel speed max. 21.5 °/s Milling depth axis (X-axis) - travel from -25 to 640 mm - max. speed 6 m/min Machinen distance (V-axis) - travel 150 mm - speed max. 1.6 m/min - 13 milling cutters included -

36.000 €

Datasheet

Request / Contact

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

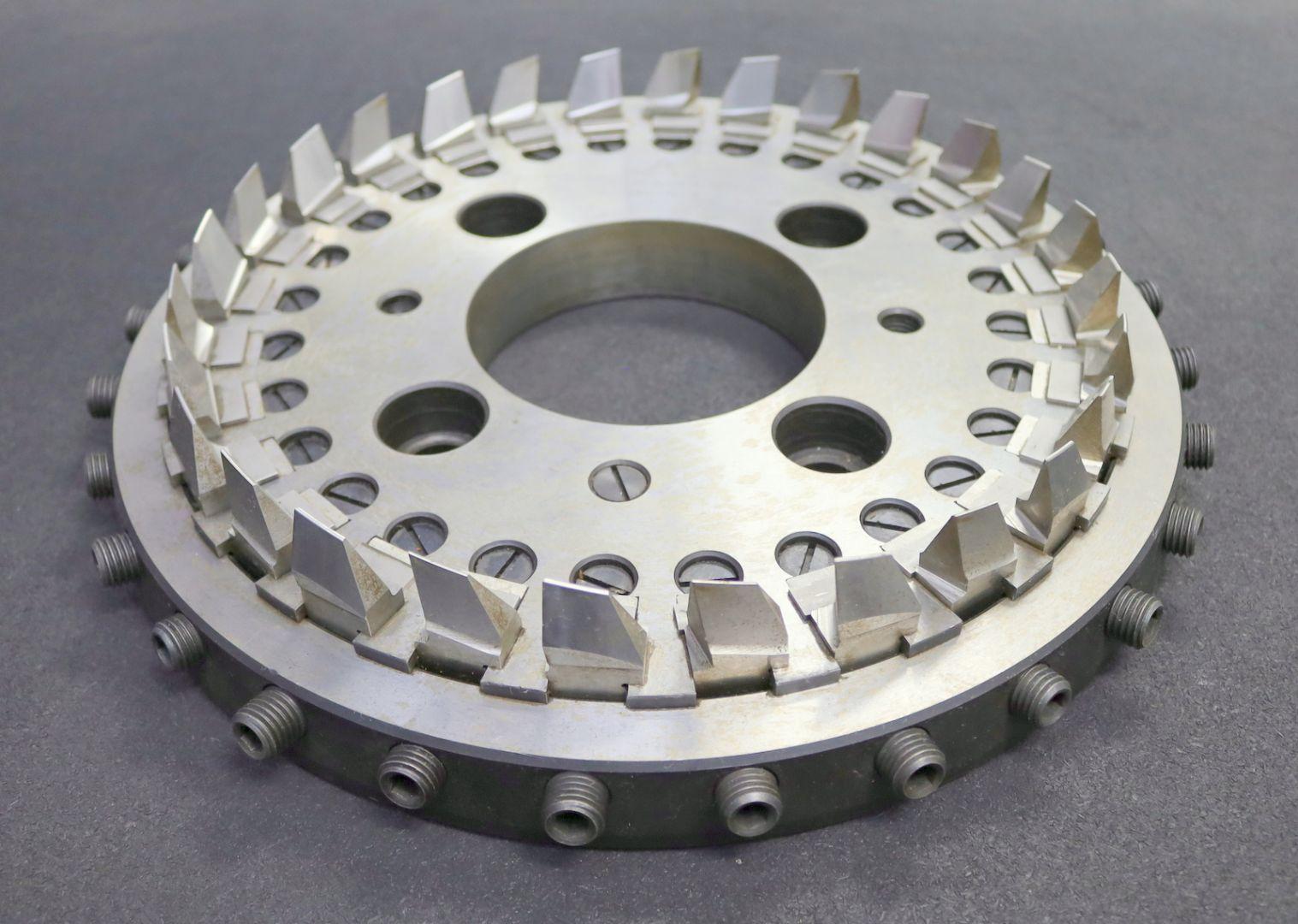

#1139-00446 · Bevel Gear Generator - Spiral

WMW-MODUL - MK 12 - - - konventionell

Technical details

WMW MODULE Arcoid cutter head MK 12" 2§m - 304.8 for bevel gears with tapered tooth height analog Gleason for bevel gear milling machine MODUL ZFTKK 500 28 knife inserts 05M VESTA WORKS 552 A-311 AJ/ck 30499005 used weight 29.4kg We have 4 different types in stock. You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.

Bevel Gear Generator - Straight

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

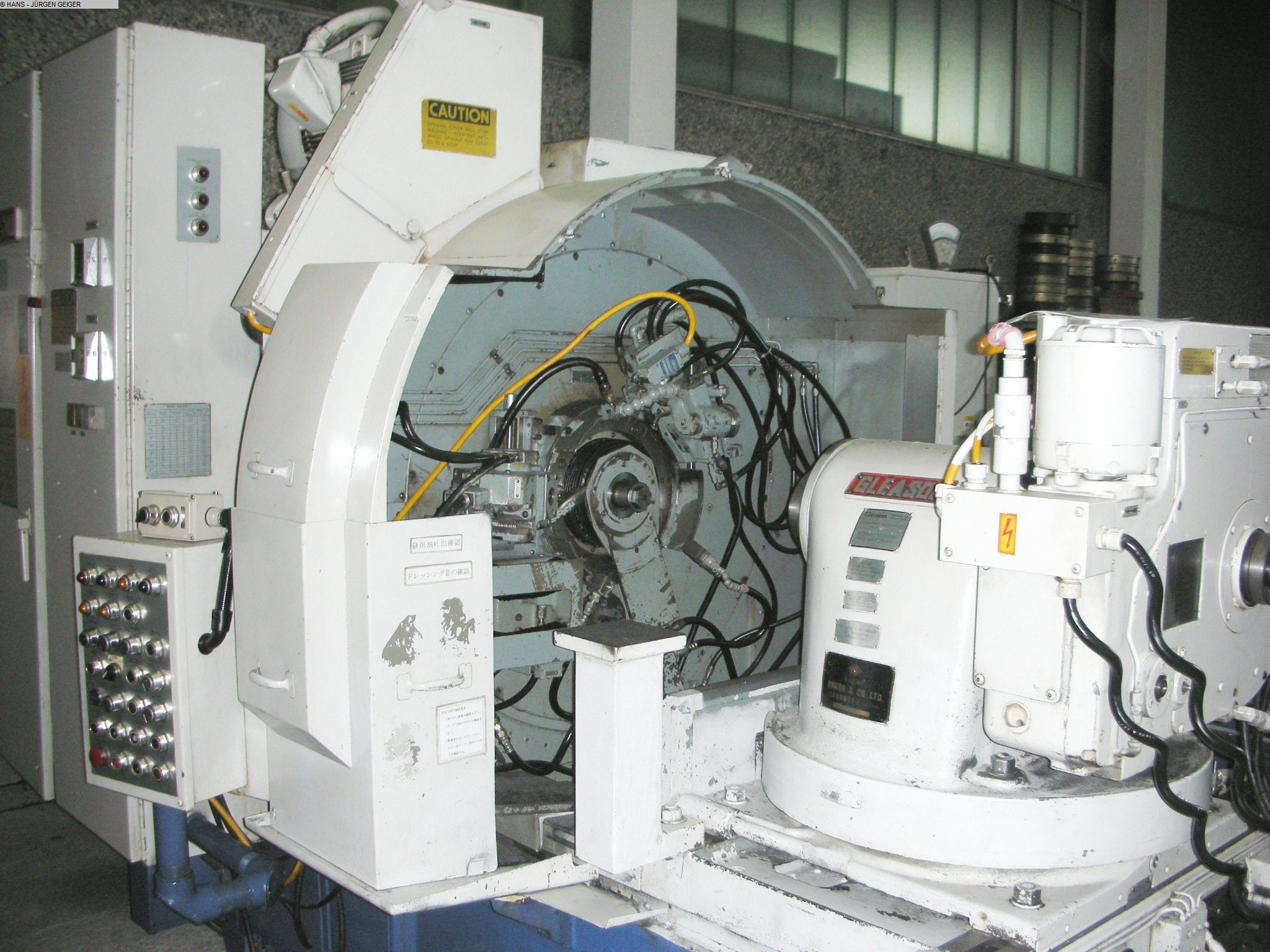

#1020-20211 · Bevel Gear Generator - Straight

GLEASON - 104 CONIFLEX - - 1997 - Fanuc 0-GC

Technical details

- CNC Control Fanuc 0-GC - Set of Change Gears For Speed, Feed and Roll, Index and Ratio Roll - Hydraulic Double-Acting Chucking Mechanism (Less Draw-in-Bar and Nut) - Self-Contained Hydraulic System - Self-Contained Coolant System - Workhead Brake - Full Guards Cover - Full Compliment of Electrics (Motor/Controls) SPECIFICATIONS: Cone Distance: 0 to 4-1/2" Pitch Angle: 84 deg. 18 min. (max); 5 deg. 42 min. (min) Extreme Ratio: 10-to-1 Pitch Diameter: 10-to-1 ratio; 8-1/2" (max) Pitch Diameter: 1-to-1 ratio; 6" (max) Diametral Pitch (coarsest): 3 DP Diametral Pitch (finest): 20 DP Face Width: 1-3/8" (max) Index Range: 9 to 93 inclusive, and most numbers up to 175 Pressure Angles: 20, 22-1/2 & 25 deg. Diameter of Taper Hole at Large : 3-29/32" Taper per Foot: 39/64" Depth of Taper: 6" Diameter of Hole Through: 2-7/16" Spindle Nose to Machine Center: 1-1/2" to 9" Cutter Speeds: 98 to 286 (feet per minute) Feeds: 4.2 to 69.2 (seconds per tooth)

Datasheet

Request / Contact

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19248 · Bevel Gear Generator - Straight

MODUL - ZFTK 500/2 - - 1988 -

Technical details

change gears coolant Chip Conveyor

Datasheet

Request / Contact

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-00397 · Bevel Gear Generator - Straight

KLINGELNBERG - - - - konventionell

Technical details

KLINGELNBERG Palloid gear hobs We have around 450 milling cutters in stock in the module range from 1-7. Manufacturer KLINGELNBERG Please contact us! You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.

Bevel Gear Grinding Machine

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17944 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2008 - SIN 840 D SIEMENS

Technical details

Hoffmann coolant filter system ERK 140-V(L-C) (built 2008) VT oil mist filter system

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17513 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2007 - 160 i - MB FANUC

Technical details

WAGURI with EWAB robot cell (KUKA Robot) no coolant filter system available

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17512 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2005 - SIN 840 D SIEMENS

Technical details

WAGURI with EWAB load cell built in 2012 (Linear loader) no coolant filter system available

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-328540 · Bevel Gear Grinding Machine

GLEASON - PHOENIX 200 HG - - 1997 -

Technical details

Max. external Ø of workpiece 215 mm Tooth profile, height x width 16 x 40.65 mm No. of teeth 5 - 200 Max. tooth ratio 1 : 10 Grinding wheel Ø 51 - 190 mm Grinding wheel speeds 1,000 - 6,000 rpm X Axis (horizontal) 152 mm Y Axis (vertical) 178 mm Z Axis (slide base plate) 304 mm Distance from middle of machine to middle of workspindle 115 mm Axial speed 125 mm/sec Workpiece speeds 0 - 30 rpm Workspindle bore, conical 3 29/32 inch Total electrical load 20 kW - 380 V - 50 Hz Weight, approx. 10,000 kg Accessories / Special Features * FANUC CNC Control, Model 150 MB, for 7 axes, with monitor and direct input. Automatic calculation of all workpiece and grinding parameters. * Extensive coolant equipment with filter system, band filter, etc. * Driven grinding wheel dressing device with CNC dressing control for automatic compensation of form and diameter after every dressing. * Gear grinding is effected either in single component operation using a conical cup wheel (Gleason 30°), or with a cylindrical cup wheel. These grinding wheels can be made of CBN, or of traditional "dressable" aluminium oxide material (question of cost). Grinding with a conical grinding wheel is of advantage with regard to heat build-up and quality of tooth contact pattern. Therefore these pairs of bevel gears (for automotive industry) can be generated in high quality with consistent accuracy, economically, and with short set-up times. Condition : Very good - machine can be inspected here under power Delivery : Ex stock, as inspected Payment : Net, after conclusion of contract Thank you for your interest. We always have a good selection of gear machines available. Please let us know what you need.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-304112 · Bevel Gear Grinding Machine

GLEASON - 120 / 888 W - - 1980 -

Technical details

Max. depth of tooth 10 mm Max. workpiece Ø (for clearance) 1,010 mm Max. external Ø of coupling 610 mm Sliding base withdraw 216 mm Max. distance from grinding wheel to workpiece nose 90 - 430 mm Max. weight of workpiece, including clamp 500 kg No. of teeth 32 to 150 Grinding wheel Ø, approx 152 - 320 mm Grinding wheel speeds, infinitely variable 0 - 3,600 rpm Work spindle bore 60 mm Total electrical load, approx. 15 kW - 380 V - 50 Hz Weight, approx. 9,500 kg Accessories / Special Features * Automatic roughing and finishing process via pre-settable counter and built-in feed cam. * Counter for number of teeth. * Counter for number of dressing cycles. * 2 built-on dressing units with three dressing diamonds for radius dressing, side dressing and wheel end dressing. * Built-on index plate for 48 teeth. * Separate coolant device with band filter. * Separate hydraulic unit. * Separate TRION oil mist exhaust. * Various small parts.

Bevel Gear Lapping Machine

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-18008 · Bevel Gear Lapping Machine

GLEASON - 600 HTL - - 2007 - GE FANUC Series 160i-M

Technical details

Own lapping system! Was also operated at a lapping center

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-EWH121 · Bevel Gear Lapping Machine

KLINGELNBERG - LKP 90 AVAU - - 2004 -

Technical details

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-18007 · Bevel Gear Lapping Machine

OERLIKON - L 60 - - 2002 - GE FANUC Series 160i-M

Technical details

Own lapping system! Was also operated at a lapping center

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-490759 · Bevel Gear Lapping Machine

KLINGELNBERG - LKR 400 A 100 - - 1974 -

Technical details

K L I N G E L N B E R G (Germany) Automatic Bevel Gear Lapping Machine Model LKR 400 A 100 Year 1974/1998 Serial No. 1890 Partially reconditioned and electrically modernized in 1998 by Welter Company _______________________________________________________ Max. Ø of crown gear 400 mm Adjustment of pinion spindle 160 / 250 mm Adjustment of crown gear spindle 115 / 265 mm Additional movements: Axial / distance / vertical, approx. + / - 2 mm Automatic tooth clearance 0 - 0.6 mm Module 1 - 10 Axial offset, up / down, each 50 mm (= axial offset travel from middle position) Bore hole of driving spindle 100 taper Bore hole of driven spindle 60 taper 6 spindle speeds 900 - 1,800 rpm Total electrical load 12 kW - 380 V - 50 Hz Weight 4,200 kg Accessories / Special Features * Hydraulic workpiece clamping for both spindles. * Automatic lapping process. Following function can be preset: Clockwise / anticlockwise movement, lapping torque, pulling and pushing movement, 4 lapping programs, etc. * Protective hood for crown gears with a diameter up to 400 mm, with automatic closing mechanism. * Separate switch cabinet. * Separate hydraulic unit, etc. Price, ex stock EUR 29,500.-- The lapping process employed by this machine greatly improves the running performance of bevel gear pairs. Pinions and gears are meshed by up to three additional movements (axial, radial and vertical) which are controlled by cams. Tooth flanks are smoothed with the help of lapping medium, and contact patterns are corrected as necessary.

Bevel Gear Shaping Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24057 · Bevel Gear Shaping Machine

HEIDENREICH & HARBECK - 60 HG - - 1958 -

Technical details

Machine condition very good compl. standard accessories with adjustment tools, change gears and measure tools video link: http://www.youtube.com/watch?v=oMI-DRWWDLA&feature=youtu.be

Datasheet

Request / Contact

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E2061 · Bevel Gear Shaping Machine

H & H - 60 HS 3 - - -

Technical details

Equipment: Change gears, planer knives, setting devices, clamping devices, ...

Bevel Gear Testing Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

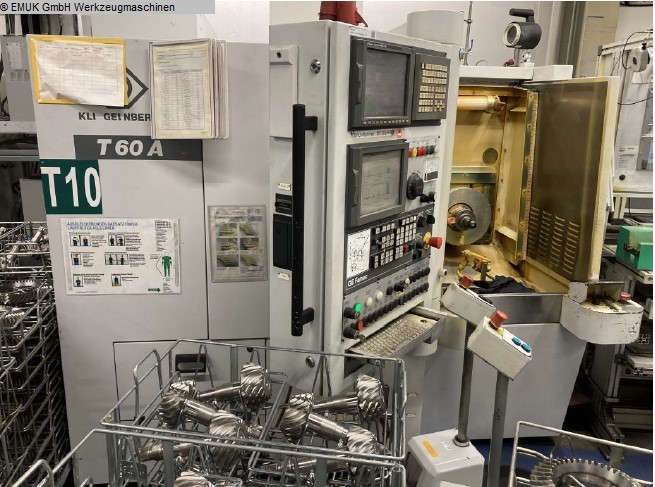

#1058-24163 · Bevel Gear Testing Machine

KLINGELNBERG - T60A - - 2007 - Fanuc 16

Technical details

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-18006 · Bevel Gear Testing Machine

OERLIKON - T50 - - 2001 -

Technical details

The Oerlikon T50 is a 3-axis CNC testing machine for fully automatic hard and soft testing of spiral and hypoid bevel gears with an axle angle of 90° Bevel gear analysis ROTEC T50 GA2 Color unit company Binks

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-385316 · Bevel Gear Testing Machine

GLEASON - 513 - - 1975 -

Technical details

G L E A S O N (USA) Hypoid Spiral Bevel Gear Running Testing Machine Model 513 TESTER, Year 1975, Serial No. 721607 This machine is very suitable for precision production testing of spiral and hypoid bevel gears with shaft angle 90°. The gear spindle is vertical and the pinion spindle is horizontal. The pinion cone distance can be adjusted while the machine is working in order to find the optimal mounting position whereby the gear is "loaded" with a preset torque. The axial pinion position can be adjusted until the quietest meshing position of the traction flank is found. Likewise, the thrust flank can be tested during the return run. Marking compound is sprayed on both sides of the teeth so the flank contact pattern can be seen. Working cycles, as well as the positioning in the tooth gap, are automatic. The gear quality can be assessed by recording the harmonic frequencies, which are displayed on a separate monitor and which can be analyzed with a RHF Control. Machine can be used for soft testing of production parts, as well as for mating sets of hardened gears and pinions prior to lapping, and for final testing after lapping to select the optimum pinion mounting distance. Also ideal for lab work, processing, and quality control. Max. gear outside diameter, approx. 508 mm Max. pinion outside diameter, approx. 254 mm Axial cross angle 90 ° Offset of pinion spindle above/below gear spindle, max. 102 mm Diameter of taper hole, pinion spindle 99/95 mm Diameter of taper hole, gear spindle 56/55 mm Speeds of pinion spindle, infinitely variable 0 - 1,250 rpm Speeds of gear spindle, infinitely variable 0 - 1,250 rpm Spindle drive, approx. 5 / 7.5 kW Total electrical load, approx. 15 kW - 380 V - 50 Hz Accessories / Special Features * Large display for 1 / 2 / 3 harmonies, display for pinion distance, pinion speed, as well of gear torque in kg/torque, etc. * Hydraulic workpiece clamping. * Hydraulic slide clamping. * Tank for marking compound with mixer and pump, separate. * Separate switch cabinet. * Separate hydraulic unit. * Lots of spare parts, spare motors, etc. Condition : Good. Machine can soon be inspected under power. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract.

Chamfering and Deburring Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-341998b · Chamfering and Deburring Machine

HURTH - ZK 200/1-TE CNC - - 1991 -

Technical details

CNC controlled milling machine for synchronous rings

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-347971 · Chamfering and Deburring Machine

PRÄWEMA - W 2 - 1 SYNCHROFORM - - 1991 -

Technical details

Workpiece Ø, min./max. 30 - 400 mm Number of teeth 6 - 150 Module range, max. 5 Tool holder shaft Ø SK 30 / 20 Tool speeds 4,000 rpm Spindle drive max. infinitely variable 1.8 kW Feeds, longitudinal and cross 0.001 - 12 m/min Workpiece speed, max. (1.5 kW) C Axis 2,000 rpm Workspindle slide 400 mm Tool speed, max. 3,000 rpm Tool holder SK 30 Total electrical load, approx. 16 kW - 380 V - 50 Hz Weight, approx. 10,000 kg Accessories / Special Features * BWO (HECKLER & KOCH) CNC Control model 785 H for altogether 7 axes. Input via monitor. The control has all the supervision and fault diagnosis features necessary for fully automatic working process. * 2 workspindle units, left and right, which can be set at any angle. * CNC controlled: Z and W Axes for tool cross slide. X and U Axes for tool longitudinal slide. * L and O Axes for milling spindle. C Axis for workspindle rotation. * Manually controlled: Tool slide rotary table (B and E Axes). Tool slide vertical infeed (V and Y Axes). Tilt of tool head (A and D Axes). All axes have digital display in the control. * Hydraulically operated workpiece clamping device in conjunction with an automatic loading device using workpiece feed / conveyor belt and swivelling loading device, as well workpiece control by air. * Coolant equipment with chip conveyor. * Noise protection cabin. * Central lubrication. * Built-on hydraulic unit. * Pneumatically driven safety doors. * Deburring device, etc. The machine uses the hypocycloidal milling principal, with electronically synchronized tool and workpiece axes for working straight roof-formed teeth, symmetric as well as asymmetric forms. Advantages are high precision and productivity. Condition : Good to very good. Machine can soon be inspected under power. Delivery : Ex stock, as inspected Payment : Net, after conclusion of contract Thank you for your interest. We always have a good selection of gear machines available on stock.

TOP Manufacturer:

LORENZ - PFAUTER - KLINGELNBERG - HURTH - GLEASON- PFAUTER - LIEBHERR - GLEASON - MAAG - REISHAUER - HOEFLER -