Band Saw - Automatic - Horizontal

Machinelist: Band Saw - Automatic - Horizontal

Band Saw - Automatic - Horizontal

- WeMa Antonius Pigge GmbH

- Barnstorfer Str. 3

- 49424 Goldenstedt

- Deutschland

-

+49 (0)444496700

+49 (0)4444967010 -

info@wema-pigge.de

www.wema-pigge.de

#2031-3676 · Band Saw - Automatic - Horizontal

MEP - Shark 280 SXI duty Halbautomat - - unbekannt -

Technical details

Datasheet

Request / Contact

- Feyen Maschinen GmbH

- Gelleperstr. 10

- 47809 Krefeld

- Deutschland

-

0049 (0)2151/5267-0

0049 (0)2151/5267-39 -

info@feyen.de

www.feyen.de

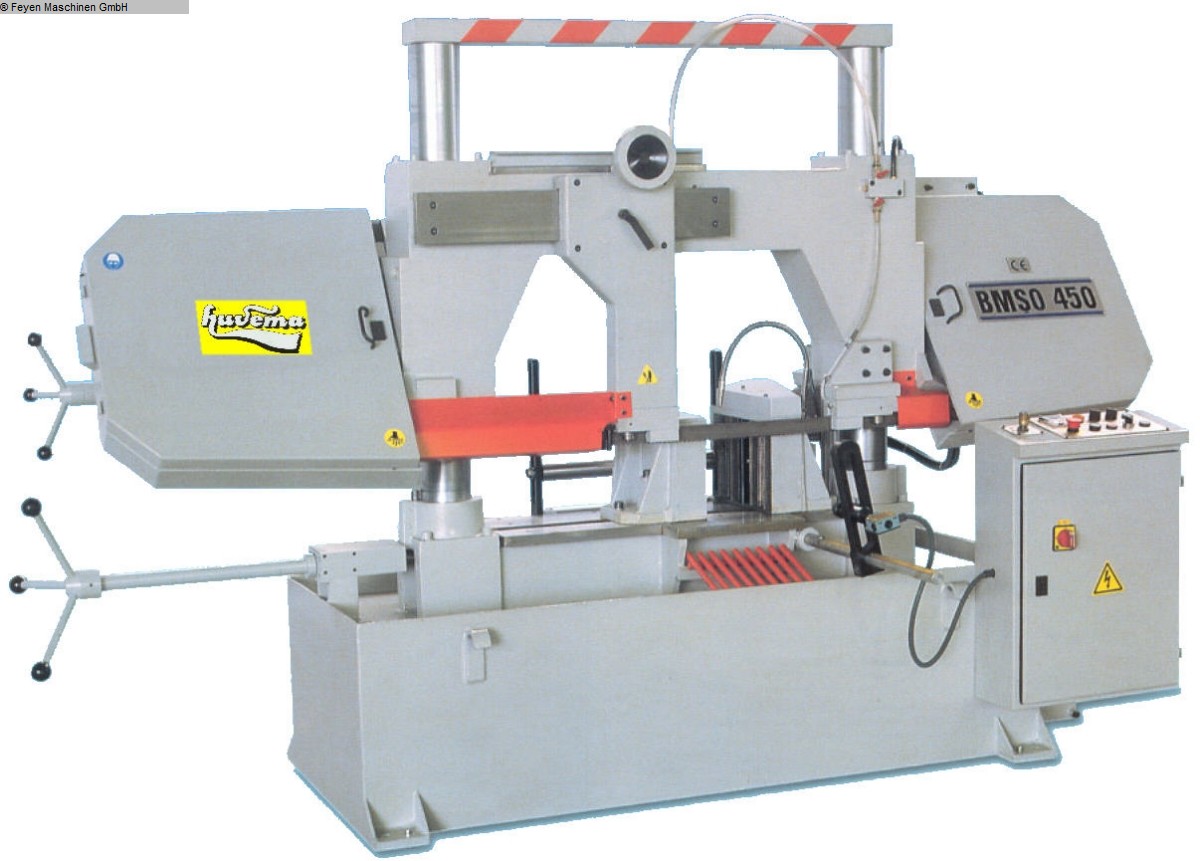

#1053-010049 · Band Saw - Automatic - Horizontal

HUVEMA - HU 320 BMSO GLH - - neu -

Technical details

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-682 · Band Saw - Automatic - Horizontal

BIANCO - 370 SA DV - - 2024 -

Technical details

hydraulicvice INCL. ADJUSTABLE CLAMPING PRESSURE saw beam moves up and down by hydraulic cylinder fast descent automatic fast up/down conrolled by feeler pin adjustable pressure according to section and type of material double safety buton for cycle start 2 speeds coolant equipment _CUTTING CYCLE_ Vice locking; Quick bow pull-down hydraulically operated; Blade rotation and cooling liquid start-up; Working pull-down; end of the cutting cycle; Stop of blade rotation and supply of cooling liquid; Quick bow lift-up; Stop of bow upwards movement; vice unlocking if selected.

Datasheet

Request / Contact

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051513 · Band Saw - Automatic - Horizontal

Beka-Mak - BMSO 320 L - - 2023 -

Technical details

On semi-automatic models the saw arm is lifted up automatically after the sawing cycle has finished. inverter hydraulic clamping hydraulic saw blade tension adjustment automatic stop ?material transport system

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051530 · Band Saw - Automatic - Horizontal

Beka-Mak - BMSO 560 C - - 2023 -

Technical details

Fully automatic band saw for cutting solid material, tubes and profiles of steel, cast-iron, light and non ferrous materials, at 90°. Entirely made of steel. The rear jaw of the hydraulic vice has a number of hardened rollers that are turned by an electric motor. The front jaw consist of a number of free running rollers. Once the work piece is clamped between the rollers no further clamping is needed. The material is fed through the vice to the material stop which contains a micro-switch controlling the feed motor. A counter controls the number of cuts. Should the blade brake the machines stop automatically. The machines are fitted with an integrated coolant pump with a removable coolant tank, which supplies coolant to both guide assemblies.

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051510 · Band Saw - Automatic - Horizontal

Beka-Mak - BMSO 320 - - 2023 -

Technical details

after the sawing cycle has finished.

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051514 · Band Saw - Automatic - Horizontal

Beka-Mak - BMSO 320 GS NC - - 2023 -

Technical details

On semi-automatic models the saw arm is lifted up automatically after the sawing cycle has finished. inverter hydraulic clamping hydraulic saw blade tension adjustment automatic stop ?material transport system

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051522 · Band Saw - Automatic - Horizontal

Beka-Mak - BMSO 350 GA Fully - - 2023 -

Technical details

Description: • Fully automatic miter band saw for sawing thick-walled Profiles and solid materials • Motorized roll feed of the material with electrical contact stop • Delta touch screen controls • Miter cutting, up to 45 ° • 1 program with 10 steps • Length accuracy 0.5 mm The feed length of the material is manually adjustable via an Microswitches selected that • Robustly constructed monoblock saw frame with hydraulic vertical movement and linear guide • Rapid advance of the saw frame with automatic transition to saw feed (Light sensor) • Infinitely variable belt speed 20 - 100 m / min • sensitive cutting pressure regulation depending on the material properties • hydraulic-mechanical belt tension • automatic guide arm adjustment, synchronized with hydraulic clamping of the Horizontal vice • Belt guidance over hard metal plates and rollers • thermal overload protection and undervoltage release • Automatic switch-off after the end of the cut • Automatic machine shutdown in the event of a belt break • Chip brush driven by an impeller

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051524 · Band Saw - Automatic - Horizontal

Beka-Mak - BMSO 360 C - - 2023 -

Technical details

Fully automatic band saw for cutting solid material, tubes and profiles of steel, cast-iron, light and non ferrous materials, at 90°. Entirely made of steel. The rear jaw of the hydraulic vice has a number of hardened rollers that are turned by an electric motor. The front jaw consist of a number of free running rollers. Once the work piece is clamped between the rollers no further clamping is needed. The material is fed through the vice to the material stop which contains a micro-switch controlling the feed motor. A counter controls the number of cuts. Should the blade brake the machines stop automatically. The machines are fitted with an integrated coolant pump with a removable coolant tank, which supplies coolant to both guide assemblies.

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051224 · Band Saw - Automatic - Horizontal

BIANCO - Mod. 420 A 60° - - 2023 -

Technical details

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051528 · Band Saw - Automatic - Horizontal

Beka-Mak - BMSO 460 C - - 2023 -

Technical details

Fully automatic band saw for cutting solid material, tubes and profiles of steel, cast-iron, light and non ferrous materials, at 90°. Entirely made of steel. The rear jaw of the hydraulic vice has a number of hardened rollers that are turned by an electric motor. The front jaw consist of a number of free running rollers. Once the work piece is clamped between the rollers no further clamping is needed. The material is fed through the vice to the material stop which contains a micro-switch controlling the feed motor. A counter controls the number of cuts. Should the blade brake the machines stop automatically. The machines are fitted with an integrated coolant pump with a removable coolant tank, which supplies coolant to both guide assemblies.

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051508 · Band Saw - Automatic - Horizontal

Beka-Mak - BMSO 230 - - 2023 -

Technical details

The HU 230 DG is a popular sawing machine and is heavily sold, due to its favourable price-quality relation. With adjustable sawing pressure, coolant pump with reservoir and electrical-mechanical saw blade tension adjustment, this machine is ideal for large workshops and small production lines. separate control panel sawing pressure hydraulically adjustable with cooling system easily moveable with stop gear wheel driven left – right mitre sawing

- RS Sperling

- von-Braun-Str. 20

- 46244 Bottrop

- Deutschland

-

+49 (0) 2045 / 41 43 22-0

+49 (0) 2045 / 41 43 22-9 -

info@rs-sperling.de

www.rs-sperling.de

#1100-051230 · Band Saw - Automatic - Horizontal

BIANCO - MOD 370 AE 60° CNC - - 2023 -

Technical details

Fully automatic metal band saw with high cutting accuracy. At this Machine are 90 ° cuts, as well as miter cuts on one side up to 45 °, continuously possible. In the manual workflow up to 30 ° (swivel range 60 °). Workflow: After entering the required number of pieces and the cut length on the control panelthe fully automatic work cycle is started. Basic equipment: - CNC control, storage of up to 99 sawing programs - hydraulic control of the cast iron saw arm - Frequency-controlled saw band drive continuously adjustable from 20 to 100 m / min - manual miter adjustment - single feed 600 mm - Height limitation of the saw frame - easy setting of the saw for miter cuts by turning the saw frame - Hydraulic clamping of the workpiece via short-stroke cylinders - Cutting pressure regulation (solid material - pipe) - electrical band tension monitoring with saw band break control - Carbide saw band guides and guide rollers - Stable underframe with coolant tray - Coolant pump with double feed to the saw band guides - Material drainage grid - Bi - metal saw band M 42 - moving chip brush

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-664 · Band Saw - Automatic - Horizontal

BIANCO - 330 AE CNC - - 2023 -

Technical details

material feed andnumber of pieces by CNC (99 programms) automatic cutting cycle clamping, saw blade and cutting fluid on, cutting operation, saw blade and cutting fluid off, fast return stroke, declamp automatic feed 600 mm/stroke variable cutting pressure variable cutting speed coolant equipment automatic saw blade breakage detection hydraulic vices for material clamping while cutting and for feeder unit user manual in GERMAN or ENGLISH

Datasheet

Request / Contact

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-1912 · Band Saw - Automatic - Horizontal

HESSE by BEKA-MAK - BMSY 270 DG - - 2022 -

Technical details

demo machine - mint condition digital angle control blade brush control panel swivel frame infinitely adjustable lowering with hydraulic cylinder hydraulic lifting of the saw frame quick lowering with automatic switchover to working speed using a sensor pin mech. Vice with quick clamping coolant equipment machine base chip collecting tray user manualin GERMAN or ENGLISH

Datasheet

Request / Contact

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-69 · Band Saw - Automatic - Horizontal

HESSE by BEKA-MAK - BMSY 320 DGH - - 2022 -

Technical details

DEMO MACHINE - MINT CONDITION Double mitre cutting Inverter Saw blade 34 Hydraulic vice Heavy duty gearbox Hydromechanic blade tension Saw band brush Digital read out for mitre angle Coolant equipment Operating manual in English or German

Datasheet

Request / Contact

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-600 · Band Saw - Automatic - Horizontal

HESSE by BEKA-MAK - BMSY 440 DGH - - 2022 -

Technical details

DEMO MACHINE - MINT CONDITION hydraulic vice digital readout for scale of bending angle hydraulic clamping of sawing arm turning of sawing arm by hand continuously variable down speed of sawing arm automatic sawing frame lifting after cutting sensitive cutting pressure adjustment subject to material condition hydromechanic tape tension readout by manometer mobile control panel angular geared conical heavy duty gear unit driven chip brush tape guiding by hard metal sheet plates and rolls automatic tape break lock HYDRAULIC UPLIFT OF SAWING FRAME user manual in GERMAN or ENGLISH

Datasheet

Request / Contact

- Feyen Maschinen GmbH

- Gelleperstr. 10

- 47809 Krefeld

- Deutschland

-

0049 (0)2151/5267-0

0049 (0)2151/5267-39 -

info@feyen.de

www.feyen.de

#1053-010021 · Band Saw - Automatic - Horizontal

HUVEMA - HU 320 BMSO - - 2020 -

Technical details

• Semi-automatic • the length of the saw will be adjusted manually to a back stop by limit switch

- Feyen Maschinen GmbH

- Gelleperstr. 10

- 47809 Krefeld

- Deutschland

-

0049 (0)2151/5267-0

0049 (0)2151/5267-39 -

info@feyen.de

www.feyen.de

#1053-010077 · Band Saw - Automatic - Horizontal

HUVEMA - BMS0 460 C - - 2019 -

Technical details

full-automatical band saw, Accessories: • Inverter for controllable speed, • automatical stop function after sawing and on breakage of the saw blade, • automatical saw arm lifting, • hydro-mechanical clamping of the saw blade, • material clamping to be effected from above, hydraulical vice, • switch for cutting pressure control, • coolant pump, • roller conveyor, length: 1.2 m.

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17942 · Band Saw - Automatic - Horizontal

KLAEGER - Actron 325 G - - 2013 - K-Tronik-E

Technical details

semi-automatic Miter setting instantaneous from 90°- 30° stepless highly stable saw frame with precise band guidance outstanding cutting performance intuitive operation of the semi-automatic powerful at the push of a button, even with miters (90 - 30° left) All machine functions on a clear control panel Ideal for the fastest sawing, especially small cross-sections Automatic lifting of the saw frame with adjustable lifting height Roller conveyor infeed 3000 mm Roller conveyor outlet 1000 mm with stop / digital display machine on wheels

Datasheet

Request / Contact

- Dahms Maschinenhandel

- Max-Planck-Str. 7

- 86757 Wallerstein

- Deutschland

-

+491737008807

-

info@werkzeugmaschinen-haendler.de

www.werkzeugmaschinen-haendler.de

#4017-001 · Band Saw - Automatic - Horizontal

KASTO - Twin A4 - - 2010 -

Technical details

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17951 · Band Saw - Automatic - Horizontal

KASTO - twinA5 - - 2009 - KASTO

Technical details

Automatic two-column band saw with KASTO Compact Control; frequency-controlled saw band drive; infeed and outfeed belt; chip conveyor

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03812 · Band Saw - Automatic - Horizontal

Kasto - HBA A10x12 - - 2005 - CNC

Technical details

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-18015 · Band Saw - Automatic - Horizontal

KALTENBACH - KBS620DG-NA/T13 - - 2003 - Kaltenbach

Technical details

Double miter KALTENBACH control workpiece eplenishment machine 650 - max. individual replenishment 3000 mm - min. cutting length 50 mm - min. remaining piece length 150mm Roller conveyor Light barrier protection

Datasheet

Request / Contact

TOP Manufacturer:

HESSE BY BEKA-MAK - BIANCO - BEKA-MAK - KASTO - MEP - VOLLAUTOMAT -