Machine data

Document

Keine weiteren Dokumente vorhandenTechnical details

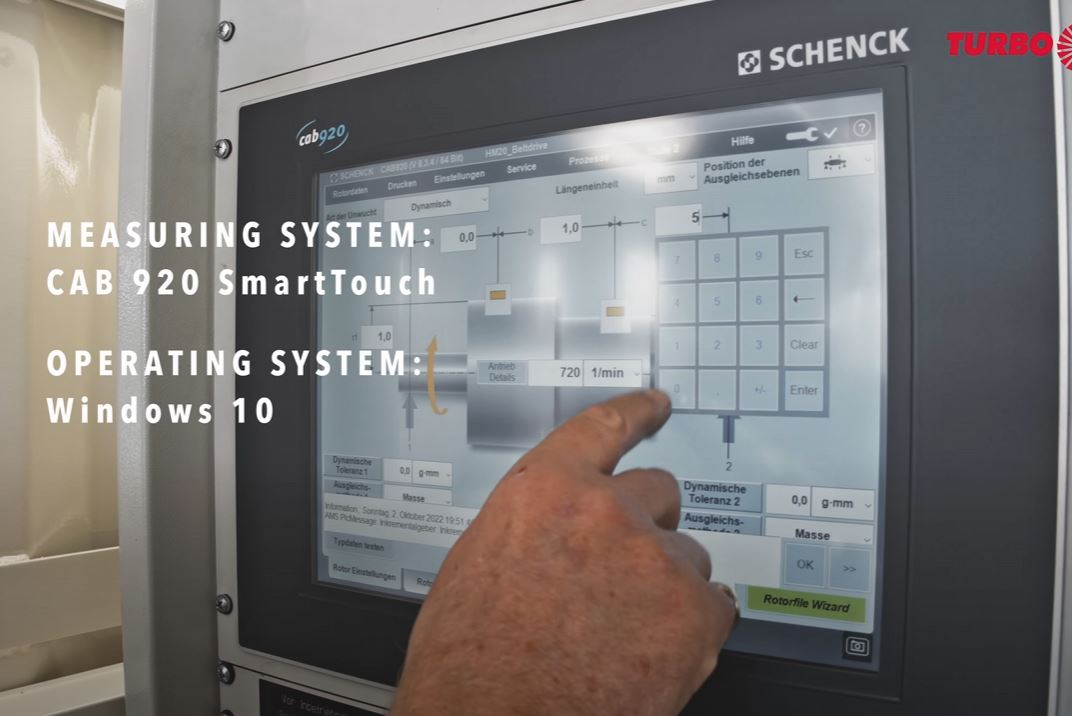

| workpiece weight | 100 - 3.000 kg |

| workpiece length | 5.000 mm |

| diameter | 1.260 - 1.600 mm |

| Control | CAP920 |

| total power requirement | 11 kW |

| weight of the machine ca. | 20 t |

| dimensions of the machine ca. | 20" Container m |

Videos

Additional information

Mobile balancing system "SCHENCK" for use anywhere in the world

The balancing system is permanently installed in a 20" open-top container.

The container is equipped with everything you need for balancing

• Lighting

• Metal base plate 12,000 kg as a base plate for accuracy

• Compressor for working air supply distributed in the container

• Compressed air connections.

• A circumferential power strip

• A tool cabinet equipped with tools

• A hydraulic lifting device for aligning the container from the outside

• In addition to a tarpaulin for the roof, the container also comes with

movable roof segments made of sheet metal.

• The container has a central plug through which the container can be connected

can be supplied with the required 380V voltage.

The system has been approved by Schenck and test protocols are available

On the following pages please find the specification for

1 Schenck balancing machine, type HM 40/HM 20

U/BU with measuring unit CAB 920 SmartTouch

We like to give you some technical comments to this balancing machine.

This machine exists in its basic version of a HM 40 U/BU. Additionally we are

offering a special pair of add. pedestals type HM 20 which can be easily

exchanged against the HM 40 pedestals. The HM 20 pedestals will enable you to

accommodate also small pump rotors into the machine.

The advantages are: only one machine base and end and belt drive with one

electrical control (space cost-saving)

The machine is installed in a open Top 20” Container as a safety enclosure.

(space and cost-saving)

The HM 40/20 U/BU covers a wide range of rotor types due to rotor weight,

dimension and balancing tolerances. This may also require fiexibility in

balancing speeds.

Therefore we have quoted the machine together with an electrical drive with

squirrel cage motor with frequency converter for variable speed.

The offered measuring unit CAB 920 is a computerized high-end unit and

especially developed to fulfil advanced balancing tasks. Data input is

extremely simple through the "Easy Mode" guiding the Operator perfectly.

Unbalance visualization is realized by big vector meter displays on a high

contrast TFT colour monitor with touch screen function. The integrated

Industrial PC runs the unique CAB 920 balancing software and provides access to

the balancing Data for direct printouts or via PC network. CAB 920 can be

adapted to specific needs by additional software packages.

For quick and accurate finding of the angular position of the measured

unbalance on the rotor by using the belt-drive the software extension 'angle

indexing" is included in the delivery extent of both measuring units. When

reaching the correet unbalance angle it will be displayed on the measuring unit.

Due to the method of correction (grinding at a [arger surface area) the vector

indication is of advantage.

Machine mode: HM 40/20 U/BU

Year of manufacturing: 2012/2021

Manufacturing number: RPHF02I7

Item Extent of delivery

Pair Bearing Pedestals HM 40

Rotor weight for symmetric bad 3000 kg

for each bearing pedestal max. 1500 kg

Largest rotor diameter above machine bed 1600 mm

Distance between bearing centres (belt drive between pedestals) min. 155

mm

upward static bearing loads for counter bearing with roller 3000 N

Limit value of permanent calibration 710 x 1 0E6 kg/min'

1.1 1 Pair of Roller Bearing lnserts HM 40

adjustable for journal bearing diameters

1.2 1 Pair of Roller Bearing Inserts HM 40

adjustable for journal bearing diameters

1.3 1 Pair Bearing Pedestals HM 20

Rotor weight for symmetric bad

for each bearing pedestal max.

Largest rotor diameter above machine bed

Distance between bearing centres (left drive between pedestals)

upward static bearing loads for counter bearing with roller

Limit value of permanent calibration

1 Pair of Roller Bearing lnserts

adjustable for journal bearing diameters 9-70 mm

1 Pair of Roller Bearing lnserts

adjustable for journal bearing diameters 70-140 mm

2 Set of counter bearings (Hold-down bracket)

The balancing machine is equipped for safety reasons with one set of counter

bearings size HM 40 and one set size HM 20 to absorb upward bearing loads. The

counter bearings are hinged and tHting out of the way for easy rotor loading

and unboading. Each set is consisting of:

- 1 x counter bearing with roh (negative bad bearing for overhanging rotors)

- 1 x counter bearing with sliding piece

1.7 2 Axial thrust stops mounted on machine base

Two axial thrust stops to be mounted on machine base for babancing big rotors

in overhanging position.

2 1 Machine Bed

with roller chain and two T-slots for moving the pedestals

easily along the machine base

bed Iength in total

consisting of 5.000 mm

1 x3000mm, 1 x2000mm

3 1 Measuring Unit

with: Operating System Windows 10 loT Enterprise 2016 LTSB

- Direct data input without keyboard via Touch-Screen-Display

- Easy Mode for simplified data input and display of results

- Indication of the result via big vectormeter and numerical displays

- Workshop tried and tested industrial PC

- Easy data export via front side USB

- Networking capability

- Optimized signal processing for high accuracy via Schenck MMD-digital filter

- Intelligent self-diagnostics of the measuring electronics

- Modular, service friendly System design

- Operation using Windows standard procedures

- Measurement of dynamic, static and couple unbalance

- Optimised menu functions

- Rotorfile Wizard

- Possibility to connect drawings or instructions to rotor files

- User level administration with individual profiles

- Numerous software modules available

- mcl. Software 'Tolerance Calculation to [SO 21940-11

- mcl. single, key- and index compensation

- mdl. measurement during run-up

- Advanced print manager

- Log report in pdf format

- Archiving in measurement value database in MS-Excel compatible format

- User dialog can be selected between English/German

Measuring range

100 – 5000 rpm

Minimum achievable residual unbalance (Umar)

acc. ISO 2953 for each plane per kg rotor weight

with belt-drive 0.1 gmm/kg

with end-drive 0.5 gmm/kg

but for HM 20 pedestals not less than 0.8 gmm

but for HM 40 pedestals not less than 4.0 gmm

Value refers to the measuring speed of 1000 rpm

Unbalance reduction ratio (URR) up to 95%

3.1 1 Indexing manually

to exactly transfer the measured unbalance angle to the rotor (manual indexing).

3.2 1 Software "Rotorspecific Calibration"

Our optional Rotor Specific Calibration software allows a "fine tuning" of the

machine to compensate for balancing tooling whose dynamic stiffness is

insufficient. The Rotor Specific Calibration software will improve the ability

to transpose the bearing plane measurements to the correction planes (plane

separation). Rotor Specific Calibration should be used when a ]arge cross

effect is noted between correction planes separated by a small distance.

Rotor Specific Calibration is also useful when the result of rotor weight and

balance speed approaches or slightly exceeds the weight-speed squared (Wn2)

rating of the machine, or when the rotor deforms while balancing (e.g., fan

blades with variable pitch). Balancing machines employing offset roller

bearings, which significantly affect the stiffness of the support bearing

system, will also benefit from the employment of Rotor Specific Calibration.

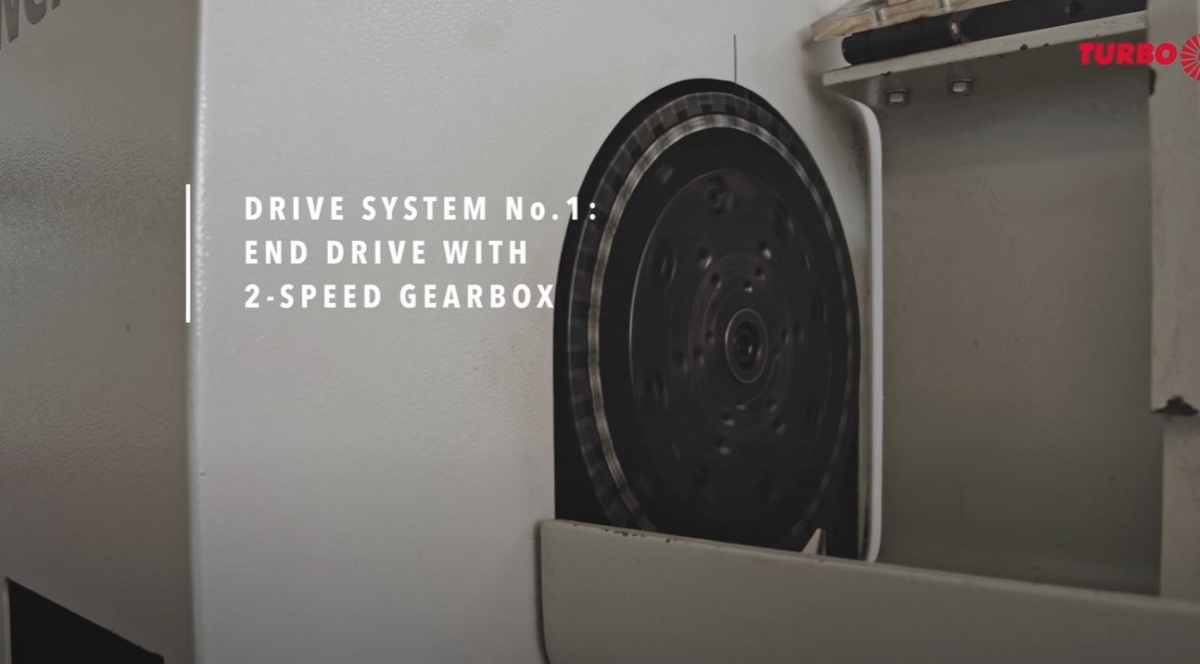

4 1 End Drive U2

Drive power 7.5 kW

Balancing speed 1. gear 60 - 580 rpm

Balancing speed 2. gear 110- 1120 rpm

Drive shafts Drive Shaft 250 Nm , Drive Shaft 80 Nm

4.1 1 Rotor locking device - end drive

4.2 1 Belt drive BU 4/5

Drive power 7.5 kW

Belt driven diameter 20 - 600 mm

Balancing speeds based upon 100 mm belt driven diameter:

140- 1460 rpm, 200-2000 rpm, 350 - 3640 rpm

4.3 1 Rotor locking device - belt drive

5 1 Electrical drive and control

for variable balancing speed, consisting of:

control cabinet prepared for installation of the measuring unit with:

- frequency converter for speed setting range 1 : 10 and energetic

recovery system

- operation devices and contactors

The balancing system is permanently installed in a 20" open-top container.

The container is equipped with everything you need for balancing

• Lighting

• Metal base plate 12,000 kg as a base plate for accuracy

• Compressor for working air supply distributed in the container

• Compressed air connections.

• A circumferential power strip

• A tool cabinet equipped with tools

• A hydraulic lifting device for aligning the container from the outside

• In addition to a tarpaulin for the roof, the container also comes with

movable roof segments made of sheet metal.

• The container has a central plug through which the container can be connected

can be supplied with the required 380V voltage.

The system has been approved by Schenck and test protocols are available

On the following pages please find the specification for

1 Schenck balancing machine, type HM 40/HM 20

U/BU with measuring unit CAB 920 SmartTouch

We like to give you some technical comments to this balancing machine.

This machine exists in its basic version of a HM 40 U/BU. Additionally we are

offering a special pair of add. pedestals type HM 20 which can be easily

exchanged against the HM 40 pedestals. The HM 20 pedestals will enable you to

accommodate also small pump rotors into the machine.

The advantages are: only one machine base and end and belt drive with one

electrical control (space cost-saving)

The machine is installed in a open Top 20” Container as a safety enclosure.

(space and cost-saving)

The HM 40/20 U/BU covers a wide range of rotor types due to rotor weight,

dimension and balancing tolerances. This may also require fiexibility in

balancing speeds.

Therefore we have quoted the machine together with an electrical drive with

squirrel cage motor with frequency converter for variable speed.

The offered measuring unit CAB 920 is a computerized high-end unit and

especially developed to fulfil advanced balancing tasks. Data input is

extremely simple through the "Easy Mode" guiding the Operator perfectly.

Unbalance visualization is realized by big vector meter displays on a high

contrast TFT colour monitor with touch screen function. The integrated

Industrial PC runs the unique CAB 920 balancing software and provides access to

the balancing Data for direct printouts or via PC network. CAB 920 can be

adapted to specific needs by additional software packages.

For quick and accurate finding of the angular position of the measured

unbalance on the rotor by using the belt-drive the software extension 'angle

indexing" is included in the delivery extent of both measuring units. When

reaching the correet unbalance angle it will be displayed on the measuring unit.

Due to the method of correction (grinding at a [arger surface area) the vector

indication is of advantage.

Machine mode: HM 40/20 U/BU

Year of manufacturing: 2012/2021

Manufacturing number: RPHF02I7

Item Extent of delivery

Pair Bearing Pedestals HM 40

Rotor weight for symmetric bad 3000 kg

for each bearing pedestal max. 1500 kg

Largest rotor diameter above machine bed 1600 mm

Distance between bearing centres (belt drive between pedestals) min. 155

mm

upward static bearing loads for counter bearing with roller 3000 N

Limit value of permanent calibration 710 x 1 0E6 kg/min'

1.1 1 Pair of Roller Bearing lnserts HM 40

adjustable for journal bearing diameters

1.2 1 Pair of Roller Bearing Inserts HM 40

adjustable for journal bearing diameters

1.3 1 Pair Bearing Pedestals HM 20

Rotor weight for symmetric bad

for each bearing pedestal max.

Largest rotor diameter above machine bed

Distance between bearing centres (left drive between pedestals)

upward static bearing loads for counter bearing with roller

Limit value of permanent calibration

1 Pair of Roller Bearing lnserts

adjustable for journal bearing diameters 9-70 mm

1 Pair of Roller Bearing lnserts

adjustable for journal bearing diameters 70-140 mm

2 Set of counter bearings (Hold-down bracket)

The balancing machine is equipped for safety reasons with one set of counter

bearings size HM 40 and one set size HM 20 to absorb upward bearing loads. The

counter bearings are hinged and tHting out of the way for easy rotor loading

and unboading. Each set is consisting of:

- 1 x counter bearing with roh (negative bad bearing for overhanging rotors)

- 1 x counter bearing with sliding piece

1.7 2 Axial thrust stops mounted on machine base

Two axial thrust stops to be mounted on machine base for babancing big rotors

in overhanging position.

2 1 Machine Bed

with roller chain and two T-slots for moving the pedestals

easily along the machine base

bed Iength in total

consisting of 5.000 mm

1 x3000mm, 1 x2000mm

3 1 Measuring Unit

with: Operating System Windows 10 loT Enterprise 2016 LTSB

- Direct data input without keyboard via Touch-Screen-Display

- Easy Mode for simplified data input and display of results

- Indication of the result via big vectormeter and numerical displays

- Workshop tried and tested industrial PC

- Easy data export via front side USB

- Networking capability

- Optimized signal processing for high accuracy via Schenck MMD-digital filter

- Intelligent self-diagnostics of the measuring electronics

- Modular, service friendly System design

- Operation using Windows standard procedures

- Measurement of dynamic, static and couple unbalance

- Optimised menu functions

- Rotorfile Wizard

- Possibility to connect drawings or instructions to rotor files

- User level administration with individual profiles

- Numerous software modules available

- mcl. Software 'Tolerance Calculation to [SO 21940-11

- mcl. single, key- and index compensation

- mdl. measurement during run-up

- Advanced print manager

- Log report in pdf format

- Archiving in measurement value database in MS-Excel compatible format

- User dialog can be selected between English/German

Measuring range

100 – 5000 rpm

Minimum achievable residual unbalance (Umar)

acc. ISO 2953 for each plane per kg rotor weight

with belt-drive 0.1 gmm/kg

with end-drive 0.5 gmm/kg

but for HM 20 pedestals not less than 0.8 gmm

but for HM 40 pedestals not less than 4.0 gmm

Value refers to the measuring speed of 1000 rpm

Unbalance reduction ratio (URR) up to 95%

3.1 1 Indexing manually

to exactly transfer the measured unbalance angle to the rotor (manual indexing).

3.2 1 Software "Rotorspecific Calibration"

Our optional Rotor Specific Calibration software allows a "fine tuning" of the

machine to compensate for balancing tooling whose dynamic stiffness is

insufficient. The Rotor Specific Calibration software will improve the ability

to transpose the bearing plane measurements to the correction planes (plane

separation). Rotor Specific Calibration should be used when a ]arge cross

effect is noted between correction planes separated by a small distance.

Rotor Specific Calibration is also useful when the result of rotor weight and

balance speed approaches or slightly exceeds the weight-speed squared (Wn2)

rating of the machine, or when the rotor deforms while balancing (e.g., fan

blades with variable pitch). Balancing machines employing offset roller

bearings, which significantly affect the stiffness of the support bearing

system, will also benefit from the employment of Rotor Specific Calibration.

4 1 End Drive U2

Drive power 7.5 kW

Balancing speed 1. gear 60 - 580 rpm

Balancing speed 2. gear 110- 1120 rpm

Drive shafts Drive Shaft 250 Nm , Drive Shaft 80 Nm

4.1 1 Rotor locking device - end drive

4.2 1 Belt drive BU 4/5

Drive power 7.5 kW

Belt driven diameter 20 - 600 mm

Balancing speeds based upon 100 mm belt driven diameter:

140- 1460 rpm, 200-2000 rpm, 350 - 3640 rpm

4.3 1 Rotor locking device - belt drive

5 1 Electrical drive and control

for variable balancing speed, consisting of:

control cabinet prepared for installation of the measuring unit with:

- frequency converter for speed setting range 1 : 10 and energetic

recovery system

- operation devices and contactors

On this page you will find a an offer on a used Balancing Machine of type HM 40/HM20 MOBIL of the company SCHENCK with year of construction 2012/ 2021 and with stock no.: 2032-1731. The machine is manufactured by the company SKM Industriemaschinen from 89264 Weißenhorn offered. The delivery time / delivery status for this machine is: immediately For more information, please refer to the details listed.

Documents & Videos

Keine weiteren Dokumente vorhanden

Machine

Balancing Machine