ATMH Werkzeugmaschinenhandel GmbH - Stockist for used machines

Machinelist:

Center Lathe

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S3522 · Center Lathe

5VDF BOEHRINGER - unbekannt - - unbekannt -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S52001 · Center Lathe

GURUTZPE - Super AT 400 - - unbekannt -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S3521 · Center Lathe

VDF - unbekannt - - unbekannt -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-AA1009 · Center Lathe

VDF-BOEHRINGER - 640 x 4000mm - - unbekannt -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S3717 · Center Lathe

VDF-HEIDENREICH & HARBECK - V3 - - unbekannt -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S5266 · Center Lathe

CAZENEUVE - HB 575 - - unbekannt -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-AA1001 · Center Lathe

OERLIKON-BOEHRINGER - DUE 500 - - 1982 -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S3727 · Center Lathe

TOS - SUS63x1250 - - 1980 -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

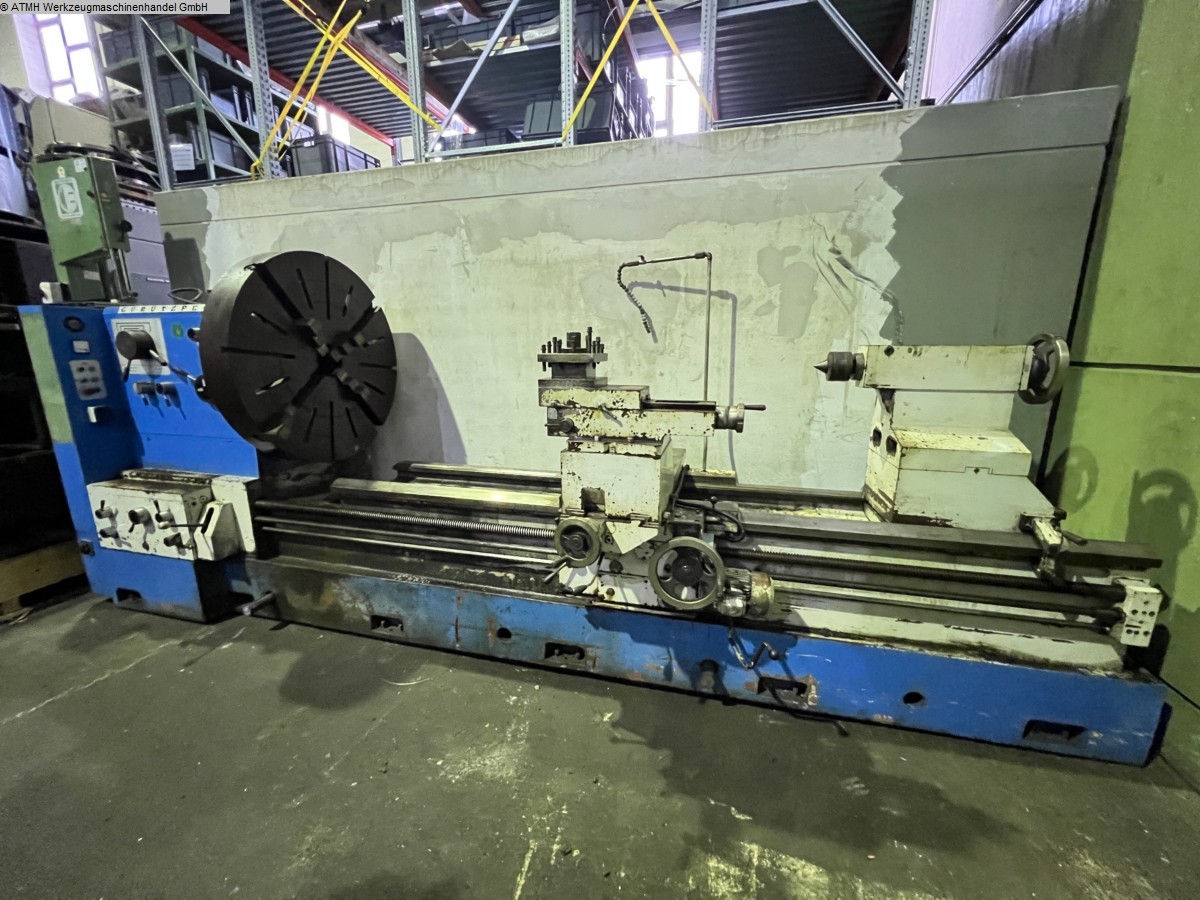

#2065-S3805 · Center Lathe

RAMO - T45-10 - - 1968 -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

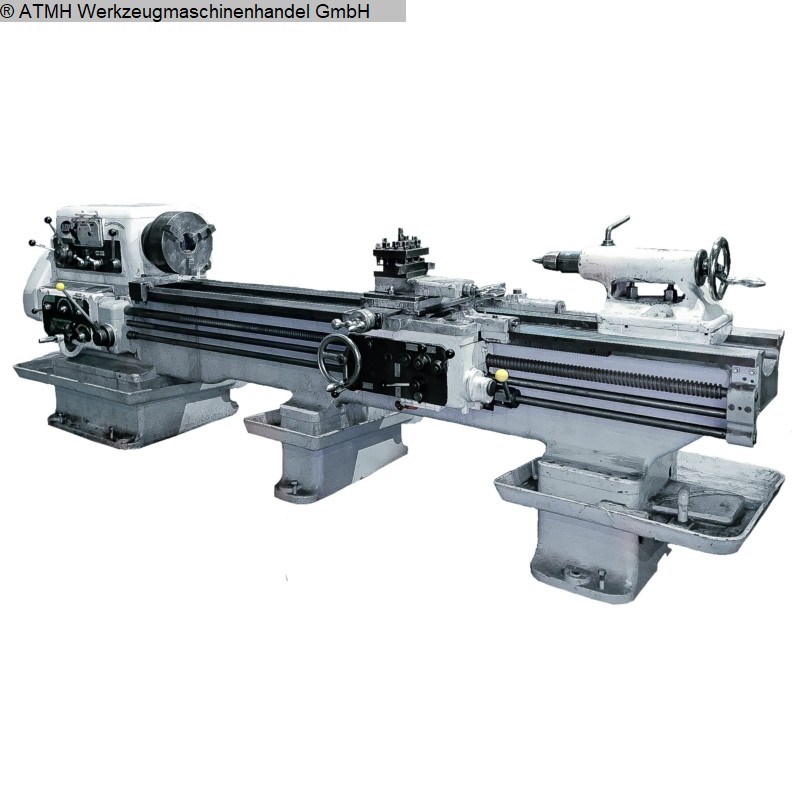

#2065-S3802 · Center Lathe

EMAG - RS1 - E - - 1961 -

Technical details

inkl. Zubehör (siehe Bilder)

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-H1148 · Center Lathe

TOS - SN55 - - 1960 -

Technical details

Datasheet

Request / Contact

CNC Lathe

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-RA1201 · CNC Lathe

WALDRICH-SIEGEN - 4000 x 1500 - - unbekannt - Siemens R&D

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S3820 · CNC Lathe

VOEST-ALPINE STEINEL - M70 x 3000 - - 1998 - SINUMERIK 840C

Technical details

VOEST-ALPINE STEINEL CNC lathe M70 x 3000 with boring bar changer Technical data/technical data: Swing diameter over bed: 750mm Swing diameter over slide: 670mm Max. flight circle turning tools: 730mm Double cross slide top 6 axes Sleigh path lengthwise / Z1: 3670mm Left carriage / X: 660 mm Right carriage / E: 660 mm Cross slide bottom 2 axes Sleigh path lengthways: 2450mm Sledge path plan: 250mm Center width/distance :3000mm Spindle/spindle: Max. speed: 3150 min-1 Spindle diameter v. Bearing: 160mm Bore diameter Spindle: 106mm Spindle head: DIN 55026 A 11 Main drive Total drive power: 63 kW Max. torque spindle: 2385 Nm Speed ??range: 10 -3150 1/min Feed force: 30000 N longitudinal/; 31500 N plan Web feed: 5000 mm/min Speed: 10000mm/min Dimensions: Length: 4665mm (machine bed) 7575mm with chip conveyor Width: 4315mm Height: 3500mm Total weight approx.: 28000kg General: Height of the turning spindle above the floor: 1233mm Height of the turning spindle above the lower edge of the machine: 1165mm Noise without processing and feed: dB(A) 80 Furnishing: -Disc turret 9+1 switching positions -Flat table turret 3+1 switching positions -Milling and drilling equipment drum mag. for drilling and milling tools (ATC) -VDI recordings/attach. VDI 3425 -4-fold revolver with quill - Full clamping cylinder OKRJ 200 from FORKARDT - Three-jaw chuck KNCS 400 92 3A11, SMW - Bezel SLU-A5-ZS-100 V, SMW company - Chip conveyor discharge height 1133 mm, width 450 mm

Datasheet

Request / Contact

Facing Lathe

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S1897 · Facing Lathe

HEYLIGENSTAEDT - 6P - - 1953 -

Technical details

Faceplate diameter: 3500mm Center height over plate: 1320mm Turning diameter over plate: 2600mm Turning diameter in the pit: 3600mm Turning diameter over bed: 1300mm Turning length: about 2400mm Max. workpiece weight: 22000kg Max. torque on the faceplate: 5000 mkg Faceplate ring gear pitch circle diameter: 1900mm Main spindle bore: 120mm range of speeds normal: 0.71-35.5 rpm increased: 1-50 rpm increased: 1.4-71 rpm Drive power: 38kW

Datasheet

Request / Contact

Heavy Duty Lathe

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S5275 · Heavy Duty Lathe

WEISSER-HEILBRONN - Gigant - CNC - - 1982 - Siemens Sinumerik 840D

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S5404 · Heavy Duty Lathe

MFD - - - 1972 - SIEMENS

Technical details

HOESCH MFD CNC HEAVY DUTY LATHE WITH SIEMENS CONTROL Coming soon to Ennepetal Technical Specifications Faceplate 2006mm Centre Height 1,499mm Swing Over Saddle 2235mm Swing Over Bed 2997mm Turning Length 12192mm Min/Max Workpiece Held In Chuck Ø457/1600mm Maximum Workpiece Weight 110 Ton Speed Range 0.5- 140rpm (300hp Motor) Feed Range 0.0118-7.08''/Rev. Steady Capacity Ø356-902mm Copying Depth 508mm lnductive Maximum Cutting Force 30,000Nm Twin Barrel Steady Capacity Ø356- 902mm, 50 Ton Capacity, Roller Type.

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-T514 · Heavy Duty Lathe

WALDRICH-SIEGEN - CNC-Drehmaschine 22000 mm - - - SIEMENS SINUMERIK 840 D

Technical details

LATHE FOR HEAVY MACHINING __________________ CONVERSION TO CNC__________________ 2006 __________________TOP WIDTH__________________ 22.000 mm __________________MAXIMUM TURNING LENGTH__________________ SUPPORT 1 20,000 mm SUPPORT 2 20,500 mm ___LARGEST TURNING DIAMETER ___ ABOVE SUPPORT 1600 mm ABOVE BED 2000 mm ____________ WORKPIECE WEIGHT____________ Max. 70,000 KG ____________PLANNING DISC____________ DIAMETER 2000 mm SPEED OF THE FACEPLATE, INFINITELY VARIABLE IN 4 STEPS 1.2 - 75 rpm MAXIMUM TORQUE AT CHARACTERISTIC SPEED 5.65 170,000 Nm MAIN ENGINE 110 kW LARGEST CLAMPING DIAMETER ON THE HEADSTOCK 1640 MM LARGEST CLAMPING DIAMETER ON THE TAILSTOCK 920 MM MOUNTING IN THE ROLLER BLOCK (PASSABLE) 2 PIECES 600 - 1290 mm MOUNTING IN STEADY RESTS (PASSABLE) 100 - 775 mm CONTROL SIEMENS SINUMERIK 840 D _________ SUPPORT 1 (TO THE HEADSTOCK) __________ TRAVEL OF THE UPPER SUPPORT 550 mm SLIDING MOVEMENT OF THE PUSHER 400 mm RAPID ADJUSTMENT LENGTHWISE (RAPID TRAVERSE) 3000 mm/min QUICK ADJUSTMENT FLAT (RAPID TRAVERSE) 1500 mm/min SLIDE HOLDER SITZMANN-HEINLEIN SYSTEM FEEDS STEPLESS FOR LONGITUDINAL 0.5 - 3000 mm/min FEEDS STEPLESS FOR FLAT 0.5 - 1500 mm/min _________ SUPPORT 2__________ MOVEMENT OF THE UPPER SUPPORT 550 mm SLIDING MOVEMENT OF THE SLIDER 400 mm RAPID ADJUSTMENT LENGTHWISE (RAPID TRAVERSE) 3000 mm/min QUICK ADJUSTMENT FLAT (RAPID TRAVERSE) 1500 mm/min SLIDE HOLDER SITZMANN-HEINLEIN SYSTEM FEEDS STEPLESS FOR LONGITUDINAL 0.5 - 3000 mm/min FEEDS STEPLESS FOR FLAT 0.5 - 1500 mm/min _________ RIDING STOCK__________ DIAMETER OF THE FACEPLATE 1200 mm QUILL DIAMETER 350 MM MAXIMUM ADJUSTMENT TRAVEL OF THE QUILL 150 mm CENTER POINT ANGLE 70° QUICK ADJUSTMENT ON THE BED 1850 mm/min _______ Revolutions of the faceplate per minute _______ 1st stage Motor speeds: 130 - 630 - 1575 Faceplate speeds: 1.2 - 5.65 - 14.2 2nd stage Motor speeds: 630 - 1575 Faceplate speeds: 10.8 - 27.2 3rd stage Motor speeds: 630 - 1575 Faceplate speeds: 15.5 - 38.8 4th stage Motor speeds: 630 - 1575 Faceplate speeds: 30 - 75

Datasheet

Request / Contact

Lathe - cycle-controlled

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-H1116 · Lathe - cycle-controlled

PINACHO - SM/200 - - 2001 - Fanuc

Technical details

Datasheet

Request / Contact

Vertical Turret Lathe - Double Column

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-AS2025 · Vertical Turret Lathe - Double Column

RAFAMET - KCF 320 / 350 - - 2000 - Typ 840 D sl

Technical details

Technical specifications Machine type: CNC vertical lathe Manufacturer: Rafamet Year of manufacture: 1973 conventional General overhaul with control retrofit 2010 Control upgrade 2016 Control: Siemens 840 D Sl Condition: very good faceplate Turning diameter of the faceplate 3,200 mm Number of rotation stages of the face plate 3 (infinitely variable) Speed ??ranges of the faceplate 0.8 - 40 rpm Level I 0.8 – 3 rpm Level II 0.8 - 11 rpm Level III 0.8 – 40 rpm processing of workpieces Max. turning diameter 3,500 mm Max. turning height of the workpieces above the faceplate 2,200 mm vertical supports Smallest axis distance between the vertical supports 470 mm Largest ram travel of the left vertical support 985 mm Largest ram travel of the right vertical support 985 mm Axis Feeds - Infinitely variable feed Max.: X1.2 3m/min max.: z1.2 2.5 m/min Plunger cannot be pivoted Support — crossbar Rapid feed of the cross beam 600 mm/min Larger distance of the cross beam to the faceplate 2,300 mm load sizes +Permissible turning force when turning workpieces with a turning diameter of 2,000 mm and a turning speed of 20 m/min. 8,000kg +Largest chip cross-section for workpieces made of steel Fz = 50 kg/mm² at a turning speed of 20 m/min for all supports 45 mm² +Largest chip cross-section for workpieces made of steel Fz = 50 kg/mm² at a rotation speed of 20 m/min for a vertical support with max. plunger length 985 mm 2.5 mm² +Largest chip cross-section for cast iron workpieces HB = 160 kg/mm² at a turning speed of 20 m/min for all supports 120 mm² +Largest chip cross-section for cast iron workpieces HB = 160 kg/mm² at a rotation speed of 20 m/min for a vertical support with max. plunger length 985 mm 22.5 mm² +Largest permitted workpiece weight at 0.8 - 3.15 rpm 17,500 kg +Largest permitted workpiece weight at 4 - 40 rpm 7,500 kg electric motors Main drive motor power and revolutions 51 kW Power of the feed motors of: - Vertical support beam (2 pieces) 16 Nm (gear 1:10) - Tappet (2 pieces) 16 Nm (gear 1:12) Power and revolutions of the drive motor of the hydraulic pumps (2 pieces) 3kW - 1,500 rpm Power and revolutions of the clamp hydraulic motor of the vertical support beam 1.5 kW - 1,500 rpm Power and rotation for crossbar adjustment 15 kW - 1500 rpm 3.5 Information on the compressed air supply and other consumables Compressed air connection: 6 bar free of oil and water 3.6 Energy Consumption Conditions Voltage: 3 x 400V Control Voltage: 24V Frequency: 50Hz Fusing: 315 A Main dimensions and weight of the machine Length 7,730mm Width 6,240mm Height: 6,700mm Weight: 85,750 kg Tool: Capto 60 recording Not powered front panel Turning diameter of the front plate 3,200 mm Clamping disc diameter 3,400 mm Number of rotation levels of the front panel 3 (continuously adjustable) Front panel speed ranges 0.8 - 40 rpm Level I 0.8 - 3 rpm Level II 0.8 - 11 rpm Level III 0.8 - 40 rpm processing of workpieces Max. turning diameter 3,500 mm Max. turning height of the workpieces above the front panel 2,200 mm Vertical supports Smallest center distance between the vertical supports 470 mm Largest glide path of the left vertical support 985 mm Maximum glide path of the right vertical support 985 mm Axis feed - stepless feed max.: X1.2 3m/min max.: z1.2 2.5 m / min Support - mirror Fast feeding of the crossbeam 600 mm/min Greater distance between the crossbar and the front panel 2,300 mm loading sizes • Permissible torque when turning workpieces with a Turning diameter of 2,000 mm and turning speed from 20 m / min. 8,000 kg • Largest chip cross-section for workpieces made of steel Fz = 50 kg / mm2 at a speed of 20 m / min for all supports 45 mm2 • Largest chip cross-section for workpieces made of steel Fz = 50 kg / mm2 at a speed of 20 m / min for a vertical support at max. piston length 985 mm 2.5 mm2 • Largest chip cross section for workpieces made of cast iron HB = 160 kg / mm2 at a speed of 20 m / min for all supports 120 mm2 • Largest chip cross section for workpieces made of cast iron HB = 160 kg / mm2 at a speed of 20 m / min for a vertical support with max. piston length 985 mm 22.5 mm2 • Largest permissible workpiece weight at 0.8 - 3.15 rpm 17,500 kg • Largest permissible workpiece weight at 4 - 40 rpm 7,500 kg electric motors Main drive motor power and revolutions 51 kW Power of the feed motors of: - Vertical support rod (2 pieces) 16 Nm (gear 1:10) - Tappet (2 pieces) 16 Nm (gear 1:12) Power and revolutions of the drive motor of hydraulic pumps (2 pieces) 3 kW - 1,500 rpm Power and revolutions of the clamp hydraulic motor of the vertical support rod 1.5 kW - 1,500 rpm Power and rotation to adjust the crossbar 15 kW - 1500 rpm Information on compressed air supply and other consumables Compressed air connection: 6 bar free of oil and water Energy consumption, conditions Voltage: 3 x 400V Control Voltage: 24V Frequency: 50Hz Protection: 315 A noise and waste emissions Noise level under load 80.4 dB (A) Sinumerik control: Type 840 D sl Main dimensions and weight of the machine Length 7,730mm Width 6,240mm Height: 6,700mm Weight: 85,750 kg Weight clamp disc: 7,500 kg

Datasheet

Request / Contact

Vertical Turret Lathe - Single Column

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S3517 · Vertical Turret Lathe - Single Column

JUNGENTHAL - unbekannt - - unbekannt -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S55000 · Vertical Turret Lathe - Single Column

BERTHIEZ - BM 225 - - unbekannt -

Technical details

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-43516 · Vertical Turret Lathe - Single Column

SCHIESS-FRORIEP - 40Dv - CNC - - 1980 - Siemens 840 C

Technical details

The SCHIESS-FRORIEP 40 DV is a vertical lathe built in 1980. The machine was modernized and improved in 1998. Among other things, a driven tool system (C-axis) was installed. In addition, the control system was modernized to SIEMENS 840 C. The large open-sided vertical boring mills with travelling column - type DV - are particularly suited to situations where likely workpieces frequently change in diameter but where maximum workpiece dimensions are rare. Decisions in favour of this type of machine are generally due to minimum floor space requirement, universal adaptability and economical advantages. The modern design of these machines is characterized by rigid all-steel construction optimized by computer - SCHIESS can claim to have done much valuable pioneering work in this area of heavy-duty machine tool building.

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S3516 · Vertical Turret Lathe - Single Column

SCHIESS - 14 DKE 100 - - 1971 -

Technical details

Machine no.: 379066 With copy facility Base, faceplate and main drive Faceplate diameter: 1000mm Distance from the floor to the top edge of the faceplate: 900mm Permissible faceplate load: 8000kg stands and crossbeams Vertical adjustment of the crossbar: 800mm Adjustment of the transom per minute: 450mm crossbar support Largest outside diameter: 1150mm Largest turning height: 1150mm Largest turning height with a workpiece diameter of up to 800m: 1750mm Largest distance between faceplate and square turret head: 1375mm Largest vertical adjustment of the turret slide: 700mm Dimension of square turret head: 400x400mm Smallest immersion diameter for the turret head: 580mm feed box Number of feeds: 24 Increment: 1.25

Datasheet

Request / Contact

Radial Drilling Machine

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S14545 · Radial Drilling Machine

RABOMA - 12Uh2000 - - 1952 -

Technical details

The pallets lying on the machine are not included in the scope of delivery.

Datasheet

Request / Contact

Atmh Werkzeugmaschinenhandel GmbH

Scharpenbergerstr.96-98

Contact Trader

Atmh Werkzeugmaschinenhandel GmbH

Scharpenbergerstr.96-98

58256 - Ennepetal

Deutschland

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75

info@atmh.de

www.atmh.de

Contact person:

Scharpenbergerstr.96-98

58256 - Ennepetal

Deutschland

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75

info@atmh.de

www.atmh.de

Contact person:

Machine category

Abgratpresse · Abkantpresse - hydraulisch · Abkantwerkzeuge · Absauganlage · Anreißplatte · Aufspannplatte · Aufspanntisch · Aufspannwinkel · Aufspannwürfel · Ausdrehkopf · Bandsäge - Automatisch · Bandsäge - horizontal · Bandsäge - Vertikal · Bearbeitungszentrum · Bearbeitungszentrum - Horizontal · Bearbeitungszentrum - Universal · Bearbeitungszentrum - Vertikal · Bettfräsmaschine - Universal · Biegemaschine horizontal · Blechentgratungsmaschine · Bohrer · Bohrwerkstisch · Bohrwerkstisch - rund · Brückenlaufkran - Zweiträger · CNC Drehmaschine · Doppelschleifbock · Doppelständerziehpresse - Hydraulisch · Drehmaschine - zyklengesteuert · Dreiwalzen - Blechbiegemaschine · Eckfräser · Eckmesserkopf · Einständerexzenterpresse · Elektronik / SPS-Steuerungen · Entmagnetisierapparat · Ersatzteile · Filteranlage · Fräs- und Drehwerkzeuge · Fräskopf · Fräsmaschine - Universal · Futter · Förderband · Gabelstapler Diesel · Gleitschleifmaschine · Handspindelpresse · Hebezange - Greifer · Hochleistungs-Metallkreissäge · Hubtische · Hubwagen - Elektro · Hydraulikaggregat · Igelfräser · Kaltkreissäge - Horizontal · Karusselldrehmaschine - Doppelständer · Karusselldrehmaschine - Einständer · Keilnutenziehmaschine · Kettenzug - elektrisch · Kompressoren · Krananlage · Krananlagen · Krantraverse · Kreissäge - Automatisch · Kugellager · Kühlmittelpumpe · Lasthebemagnete · Leit- und Zugspindeldrehmaschine · Lichtschranke · Luftgesenkhammer · Lynette · Magnetspannplatte · Messerkopf · Messmaschine · Messplatte · Meßmittel · Motor · Nutenfräser · Plandrehmaschine · Planscheibe · Plattenfeld · Polierbock · Portalfräsmaschine · Profil- Ring- Biegemaschine · Pumpenaggregat · Radialbohrmaschine · Radsatzdrehmaschine · Reinigungsanlage · Reitstock · Richt- und Biegepresse · Richtpresse - Doppelständer · Richtpresse - Einständer · Rohrausschleifer · Rollenbock · Rundschleifmaschine · Rundtisch · Schaftfräser · Scheibenfräser · Schleifbock · Schleifscheiben-Auswuchtwaage · Schleifscheibenflansch · Schnellwechsel Stahlhalter · Schraubstock · Schrumpfgerät / Induktionsgerät · Schutzgasschweißanlage · Schweißdrehtisch - rund · Schweißkantenabschrägmaschine · Schweißmaschine - Rundnaht · Schweißmaschine Längsnaht u. Rundnaht · Schweißplatte · Schweißtisch · Schwenkbiegemaschine · Schwerdrehbank · Schwerdrehmaschine · Schwerlastregal · Senkrecht - Stoßmaschine · Sondermaschine · Sonstige · Sonstige Fördertechnik · Sonstige Geräte und Zubehör · Sonstige Lagertechnik · Sonstiges · Spanngerät · Spannmittel · Spanntisch · Spitzendrehmaschine · Späneförderer · Stanzautomat-Doppelständer · Stromaggregat · Ständerbohrmaschine · Säulenbohrmaschine · Tafelschere - hydraulisch · Teilapparat · Temperiergerät · Tieflochbohrmaschine · Tischbohrmaschine · Transformator · Tuschierpresse · Vertikalteiltisch - Automatisch · Waage · Walzenstirnfräser · Wendeplattenfräser · Wendeschneidplatten · Werkbänke · Werkstattpresse - hydraulisch · Werkzeug Voreinstellgerät · Werkzeugaufnahme · Werkzeugfräsmaschine - Universal · Werkzeughalter · Werkzeughalter (angetrieben) · Werkzeugschleifmaschine · Werkzeugschrank · Winkeltisch · Zentrierspitze · Ölkühlgerät ·