Gear Testing Machine

Machinelist: Gear Testing Machine

Gear Testing Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23114 · Gear Testing Machine

PFAUTER - Zahnräder / Wechselräder P 251 - - unbekannt -

Technical details

Datasheet

Request / Contact

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-16810 · Gear Testing Machine

HOEFLER - EMZ 632 - - overhauled - Wenzel Win Geco CNC

Technical details

Gear Test Center will be completely overhauled after Order and equipped with latest control system and software -- Wenzel Win Geco CNC (4 axes) -- Renishaw SP 80H measuring head -- Renishaw measuring systems in X-Y-Z axis -- Heidenhain Exe102 for signal adjustment Turntable SIN/TTL -- Metrotek Software - T-Stylus software: definition of the probes - Software T-Cali: Calibration of the probes - Software T-Align: The eccentricity and tilt of the workpiece axis are determined with the T-Align software. - Software T-Gear for the measurement of: profile, flank, pitch and runout External and internal gears, evaluation of the measurement results according to DIN, AGMA, ISO, Measuring in metric or inch - further software available on request - Conversion is carried out to customer order - Pictures show a completely overhauled machine in new condition - Laser measurement after conversion with highest measuring accuracy - 12 months warranty

Datasheet

Request / Contact

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E23069 · Gear Testing Machine

Frenco - ZW 401 - - 2014 - Frenco

Technical details

- Leyendecker & Hollmann GmbH

- Giesenheide 18

- 40724 Hilden

- Deutschland

-

+49 (2103) 28097-0

+49 (2103) 28097-99 -

info@LHmachine.com

www.LHmachine.com

#1083-03104 · Gear Testing Machine

OERLIKON-KLINGELNBERG - R30 - - 2007 -

Technical details

Test method: - Single flank rolling test - Double flank rolling test - Structure-borne noise test - Heli testing in two-flank contact. Features: - Use of up to 6 test slides - Highest testing accuracy and repeatability - Machine table with workpiece drive - Swiveling pneumatic unit - Spray oil lubrication (type: Vogel) - Oil mist extraction (type: Elbaron)

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23251 · Gear Testing Machine

KLINGELNBERG-OERLIKON - CS 200 - - 2004 -

Technical details

In the manufacturing process for spiral-toothed bevel gears, the quality of the gear cutting gear cutting tools used plays a decisive role. Particularly in high gear cutting quality and a long service life can only be achieved with precisely can only be achieved with precisely adjusted cutterheads. The Oerlikon cutterhead setting and testing device CS 200 enables quick and easy setting of the individual knives and simple adjustment of the individual knives, it checks the position and documents the measurement results. The measuring sequence on the CNC-controlled testing device is partially automated: The individual actions for carrying out the actions for carrying out the sequence are displayed on the screen via the operator guidance. The positioning of the individual knives in the cutter head and the height of the knife tips is largely automatic thanks to a special sequence and is simultaneously documented by means of a run-out diagram. A subsequent measuring sequence checks the radial position of the inner and outer cutting edges of all knives in the cutterhead. If individual test parameters on the knives do not correspond to the the tolerance specifications, this can be individually repositioned. The combination of semi-automated setting sequence, operator-guided set-up actions and automatic operator-guided set-up actions and automatic measuring sequence, cutterheads can be can be set conveniently, quickly and with high precision. Operator-guided setting and test sequence - Graphic display of the cutter head design and the measurement results with tolerance check - Instructions for the operator in plain text Instructions for the operator in plain text (without coded information) - Simple assignment of the measurement results to the knives - Documentation of the setting and measurement results via printer- Setting and test sequence suitable for ARCON®, RSR, Spirapid, SPIRON®, TRI-AC® types - Interface for neutral data

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23250 · Gear Testing Machine

KLINGELNBERG-OERLIKON - CS 200 - - 2002 -

Technical details

In the manufacturing process for spiral-toothed bevel gears, the quality of the gear cutting gear cutting tools used plays a decisive role. Particularly in high gear cutting quality and a long service life can only be achieved with precisely can only be achieved with precisely adjusted cutterheads. The Oerlikon cutterhead setting and testing device CS 200 enables quick and easy setting of the individual knives and simple adjustment of the individual knives, it checks the position and documents the measurement results. The measuring sequence on the CNC-controlled testing device is partially automated: The individual actions for carrying out the actions for carrying out the sequence are displayed on the screen via the operator guidance. The positioning of the individual knives in the cutter head and the height of the knife tips is largely automatic thanks to a special sequence and is simultaneously documented by means of a run-out diagram. A subsequent measuring sequence checks the radial position of the inner and outer cutting edges of all knives in the cutterhead. If individual test parameters on the knives do not correspond to the the tolerance specifications, this can be individually repositioned. The combination of semi-automated setting sequence, operator-guided set-up actions and automatic operator-guided set-up actions and automatic measuring sequence, cutterheads can be can be set conveniently, quickly and with high precision. Operator-guided setting and test sequence - Graphic display of the cutter head design and the measurement results with tolerance check - Instructions for the operator in plain text Instructions for the operator in plain text (without coded information) - Simple assignment of the measurement results to the knives - Documentation of the setting and measurement results via printer- Setting and test sequence suitable for ARCON®, RSR, Spirapid, SPIRON®, TRI-AC® types - Interface for neutral data

Datasheet

Request / Contact

- ADEM MASCHINEN GMBH

- Karl-Benz-Straße 1

- 40764 Langenfeld (Rheinland)

- Deutschland

-

+49 (0) 2173- 287 77 07

+49 (0) 2173- 287 77 05 -

adem-maschinen@t-online.de

www.adem-maschinen.com

#2000-324 · Gear Testing Machine

HÖFLER - H1301/1400 - - 1992 -

Technical details

Datasheet

Request / Contact

- Leyendecker & Hollmann GmbH

- Giesenheide 18

- 40724 Hilden

- Deutschland

-

+49 (2103) 28097-0

+49 (2103) 28097-99 -

info@LHmachine.com

www.LHmachine.com

#1083-02212 · Gear Testing Machine

HÖFLER - EMZ 2002 / 2602 - - 1991 -

Technical details

Machine can be inspected under power. Setting-up and installation at the customers' is possible against extra charges. Equipment / Accessories: - clamping table diameter 1100 mm - steady rest - clamping devices - carriers - levelling shoes - hardware updated to Windows 7 - gears / straight and helical - internal and external gears - measuring of tool cutters (grinding wheels, shaving cutters, milling cutters)

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E2182 · Gear Testing Machine

HOEFLER - EMZ 632 - - 1990 - Zeiss

Technical details

Check the profile, the tooth trace and the pitch on external and internal toothed straight and helical gears. Software hob program! Software Unknown interlocking!

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-255595 · Gear Testing Machine

HOEFLER - EMZ 400 - - 1988 -

Technical details

H O E F L E R (Germany) CNC Controlled 4 Axis Inspection Centre for Gears Model EMZ 400 Year 1988 Serial No. 067 047 ____________________________________________________ Working range: Min./max. gear Ø / base circle Ø 0 – 400 / 390 mm Module range 0.5 – 15 Gear width, max. 500 mm Travel of measuring head, approx. +/- 180 mm Helix angle 0 – 60 ° Max. weight of workpiece, approx. 250 kg Distance between centres, approx. 1,000 mm Distance between centre and body of counter steady 205 mm Table Ø, approx. 290 mm Plotter diagram scales 50 / 100 / 500 / 1000 / 200 : 1 Total electrical load, approx. 1.5 kW - 380 V - 50 Hz Weight 2,000 kg Machine is suitable for measuring: Profile and flank lines on a chosen number of teeth on the gear circumference, as well as tooth pitch and runout tests of gears with straight and helical teeth. Accessories / Special Features ? HOEFLER CNC Measuring Control in 4 axes, with monitor and input terminal, for automatic measuring of various gear profiles on known and unknown (with regard to profile) workpieces. ? X = tangential adjustment of measuring head (cross). ? Y = Radial adjustment of complete measuring slide (250 mm) ? Z = Vertical travel of measuring slide. ? C = Table rotation. ? Automatic feed-in of 3-D measuring probe into the base circle and into tooth gap. ? Automatic evaluation of measuring results according to DIN or AGMA. Printing of results, via plotter or a printer. ? Separate HP Workstation, Model 382, the operator carries on a dialog with the computer during the Measuring process via keyboard. The CNC control of the machine is only needed for installation and Maintenance. ? Flexible hand-held control unit allows manual control of the axes for quick feed or creep feed. Inside the system we have a measuring software available which is developed for the MERCEDES BENZ Company, however all standard gears can be measured with this software. The Machine was recently checked through by a HÖFLER Specialist Condition : Very good – machine can inspected under power by appointment Delivery : Ex stock, as inspected Payment : Net, after conclusion of contract

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-09135 · Gear Testing Machine

KLINGELNBERG - PFSU 1600 HP - - 1985/95 -

Technical details

Universal Involute and Helix Testing Machine - modernized 1995 Machine is suitable for measuring all individual tooth data on straight and helical spur gears, and shaping and shaving cutters. Following tooth data can be tested: Tooth flanks, Involute base circle dia. and pressure angle; Profile corrections; Helix angles and leads; Lines of contact; Surface roughness; Concentricity of teeth; Tooth to tooth pitch error; Tooth thickness and tooth width over several teeth, Lots of other measuring possibilities. Accesories / Special Features: + Optical setting of base circle and optical angle settings without the use of base circle plates + Heavy workpieces can be tested on the machine. Motor-driven testing process, or manual control using hand wheels. + Auxiliary rotary table, dia. 480 mm, for mounting larger gears, with 2 sets of extending supports 400 and 470 mm long + Counter bracket Model AV 17 with maximum mounting length of 1150 mm + Separate electric cabinet for controlling manual movements, in conjunction with... + GFM Computer, Model ZMP 20 e with software for automatic dressing of gears,for the production of modern measuring printouts with graphics. The graphics are also displayed on a monitor. Various sub-programs and HP printer + Varous probe inserts and small parts, as well as a height adjustable holder for an indexing device, mounted on the back of the machine (but without the indexing device) Levelling feet in very good working condition - Machine can be inspected under power - Serial-Number B 2281

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-375218 · Gear Testing Machine

KLINGELNBERG - PFSU 2500 - - 1980 -

Technical details

Extra große ZR-Prüfmaschine, Gegenhalter

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-559494 · Gear Testing Machine

MAHR - 894 C - - 1980 -

Technical details

Manual Two Flank Gear Tester

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-422129 · Gear Testing Machine

KLINGELNBERG - PFSU 1600 - - 1975 -

Technical details

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-547677 · Gear Testing Machine

MAHR - 895 - - 1965 -

Technical details

Two Flank Gear Tester

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-568700 · Gear Testing Machine

MAAG - DAS 1 - - 1945 -

Technical details

Manually operated 2-Flank Gear Tester

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-02626 · Gear Testing Machine

MAAG - PZH 60 - - -

Technical details

- SK Maschinen-Service GmbH

- Tackweg 4

- 47918 Tönisvorst

- Deutschland

-

02151 79350

02151 793535 -

info@sk-maschinen.de

www.sk-maschinen.de

#1038-80287 · Gear Testing Machine

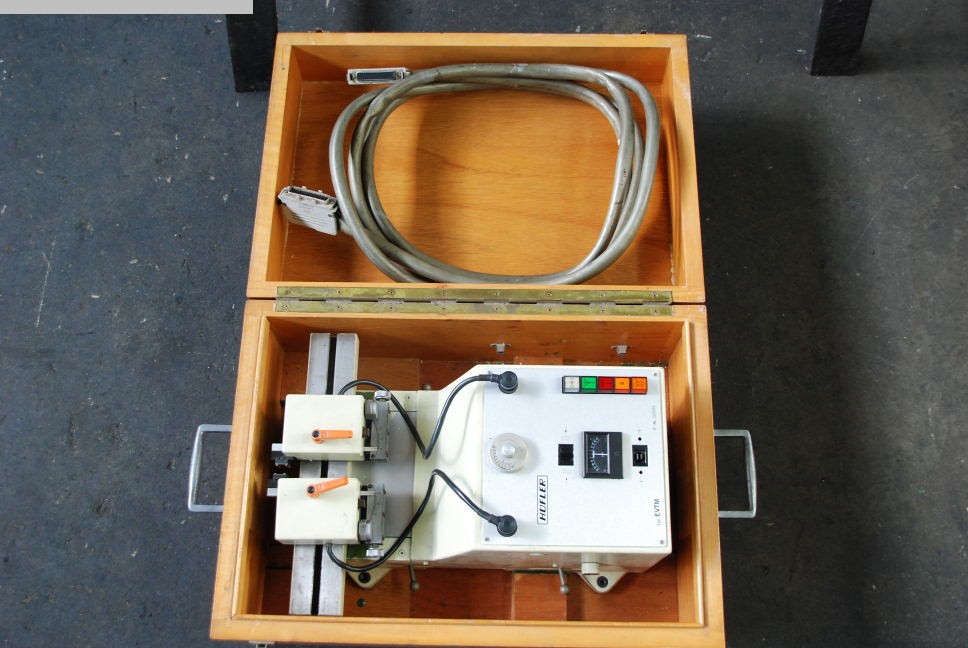

HOEFLER - EVTM - - -

Technical details

pitch and run-out tester unit for gear measuring machines.

- ADEM MASCHINEN GMBH

- Karl-Benz-Straße 1

- 40764 Langenfeld (Rheinland)

- Deutschland

-

+49 (0) 2173- 287 77 07

+49 (0) 2173- 287 77 05 -

adem-maschinen@t-online.de

www.adem-maschinen.com

#2000-378 · Gear Testing Machine

KLINGELNBERG - PNC 30 - - - ---

Technical details

Datasheet

Request / Contact

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E18634 · Gear Testing Machine

MAAG - RPG 603 - - -

Technical details

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E18640 · Gear Testing Machine

MAHR - AWG 402 - - -

Technical details

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E18643 · Gear Testing Machine

MAAG - RPG 613 - - -

Technical details

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E23050 · Gear Testing Machine

HOEFLER - EMZ 631 - - - IBH Macro

Technical details

Spur gear software for internal and external gearing Profile inspection standard crowning head - root relief K - profile Direction test standard crowning head - root relief K - profile graduation test Axis position correction for on-the-fly measurements up to 0.2 mm axis position error Snail software 3 carriers for gears, 1 carrier block, calibration device