Heinz Sanders GmbH Maschinen - Werkzeuge - Schweisstechnik - Stockist for used machines

Machinelist:

CNC Lathe

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6506 · CNC Lathe

YUNNAN - CY-K660T - - 2013 -

Technical details

**First commissioned in 2015, very good condition** - FANUC Series 18i TB Control, Manual Guide i Function - Central control panel for machine and CNC control on the pedal arm 45 ° swiveling - 12-fold tool turret - Fanuc drive with 30 kW (50% ED) - Chip conveyor - Bezel - 3 jaw chucks

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7008 · CNC Lathe

ARIX - TNC - 430 - - 2013 - CNC

Technical details

Furnishing: - 3-jaw chuck Ø200 mm - 4 compartment steel holder - Coolant device - Machine light

Datasheet

Request / Contact

lathe-conventional-electronic

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

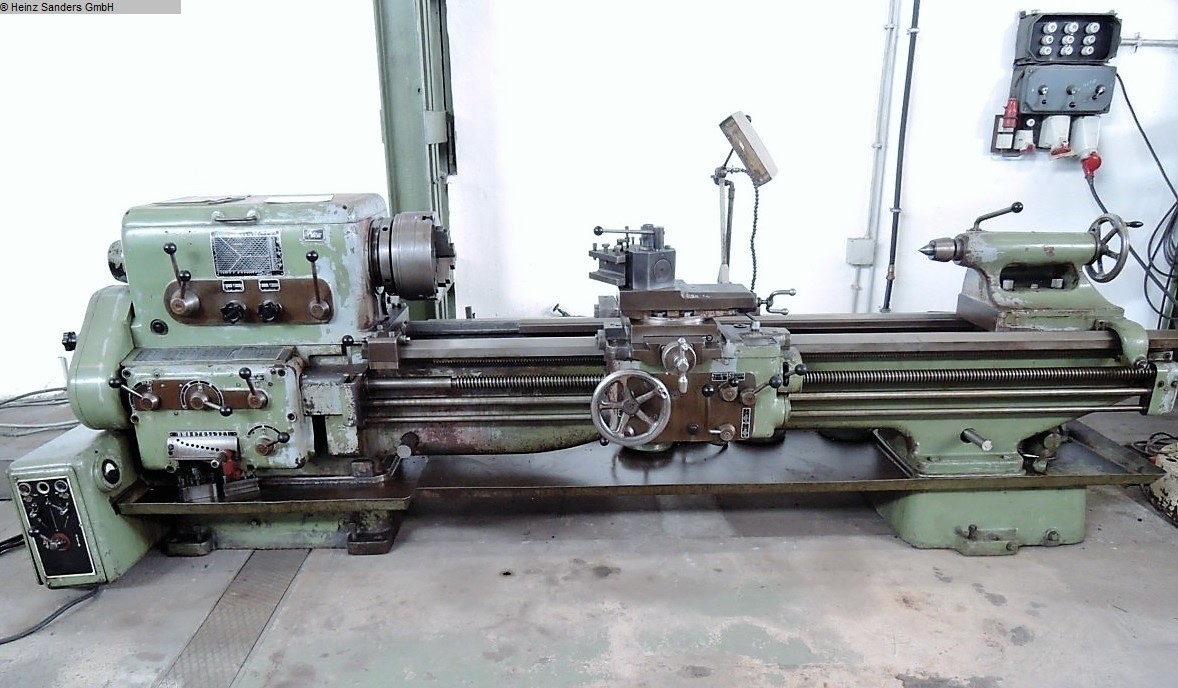

#1125-6040 · lathe-conventional-electronic

MVE BAUART VDF - V 5 - 2000 - - unbekannt -

Technical details

Electric 380Volt 3-jaw chuck Forkardt F 315 Quick change steel holder with various inserts machine light Machine feet (6 pieces) Revolving tip Coolant system

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6622 · lathe-conventional-electronic

WEILER - Praktikant - - unbekannt -

Technical details

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200006 · lathe-conventional-electronic

ZMM - C10T - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200003 · lathe-conventional-electronic

ZMM - CU325/1000 - - NEU -

Technical details

Furnishing: - Cooling device - Machine light - chip rear wall - Spindle protection - Lathe chuck protection - Tool holder protection - Foot pedal with braking function CE - Interchangeable gears *incl. Optional equipment - 3-jaw chuck Ø 160 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type A, incl. 4 tool holders - 2-axis digital display DRO Newall

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200001 · lathe-conventional-electronic

OPTIMUM - OPTIturn TH4215D - - NEU -

Technical details

Fully equipped master and feed spindle lathes. TH 4215 with digital position indicator DPA 21 / 3462070 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 6 - Precisely crafted slide - Hand wheels with adjustable fine scaling 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Adjustment range top slide ± 90° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Main spindle running in oil bath - Smooth-running gear wheels, hardened and ground with 2 adjustable Precision tapered roller bearings - Hand wheels decoupled and tested according to EN 23125 - Two-channel right-left switch tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - All metric pitches in the range 0.2 to 14mm/rev and all Inch threads in the range of 72 - 2 threads per inch without changing the Change gears adjustable by shift lever in the control panel - Clockwise/counterclockwise rotation can be switched on the bed slide via the switching spindle - Central lubrication in bed slide - Meehanite cast base and machine bed in one piece - Lead screw cover - Emergency stop device with foot control - Safety handwheels with snap-out function in the X and Z axes - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and hand wheel with adjustable fine scaling 0.025 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, induction hardened and precision ground cast iron - Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN - LED machine lamp in the chip guard Models TH 4210D and TH 4215D with digital readout DPA21 - User-friendly membrane keyboard, splash-proof, closed andglare-free - Glass scales scope of delivery - Fixed bezel passage Ø 15 - 145 mm - Revolving bezel passage Ø 10 - 75 mm - LED machine light - Reducing sleeve MT 6 / MT 4 - Fixed center MK 4 - Change gear set - Position stop with fine adjustment - Initial filling of the machine with quality oil - Operating tool ** Incl. special accessory OPTIMUM three-jaw lathe chuck centrically clamping Ø 250 mm ** Quick change holder SWH5-B set

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7375 · lathe-conventional-electronic

OPTIMUM - OPTIturn TH 3309D - - NEU -

Technical details

Fully equipped leading and tension spindle lathes. TH 3309D with digital position indicator DPA 21/3402040 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 4 - Precisely crafted slide - Handwheels with adjustable fine scale 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Main spindle running in an oil bath - Gear wheels run smoothly, hardened and ground - Upper slide adjustment range ± 90 ° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Handwheels decoupled and tested according to EN 23125 - Safety handwheels with push-out function in the X and Z axes - Two-channel right-left switch tested according to EN 23125 - DC 24 volt electrical system with two-channel safety circuit according to EN 23125 - Lathe chuck protection tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - Lockable main switch - Clockwise / counterclockwise rotation on the bed slide switchable - Lead screw cover - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and handwheel with adjustable fine scale 0.02 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, inductively hardened and precision ground - Machine base with tool compartment on the right-hand side (left-hand side with 3 Bezels (no compartments) - Pull-out chip tray with guide rails - Emergency stop device with foot actuation - LED machine lamp integrated in the chip guard Digital position indicator DPA 21 - User-friendly membrane keyboard, splash-proof, closed and glare-free - glass rulers scope of delivery - Fixed steady rest passage Ø 6 - Ø 50 mm - Moving steady rest passage Ø 8 - Ø 30 mm - LED machine light - Reduction sleeve MK 5 / MK 3 - Two fixed centering points MK 3 - Quadruple steel holder 16 mm - Change gears set - machine base - Initial machine filling with quality oil - operating tool ** Including special accessories OPTIMUM three-jaw lathe chuck, centric clamping Ø 200 mm Camlock DIN ISO 702-2 No. 4/3442762

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200004 · lathe-conventional-electronic

ZMM - C10TM/3000 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

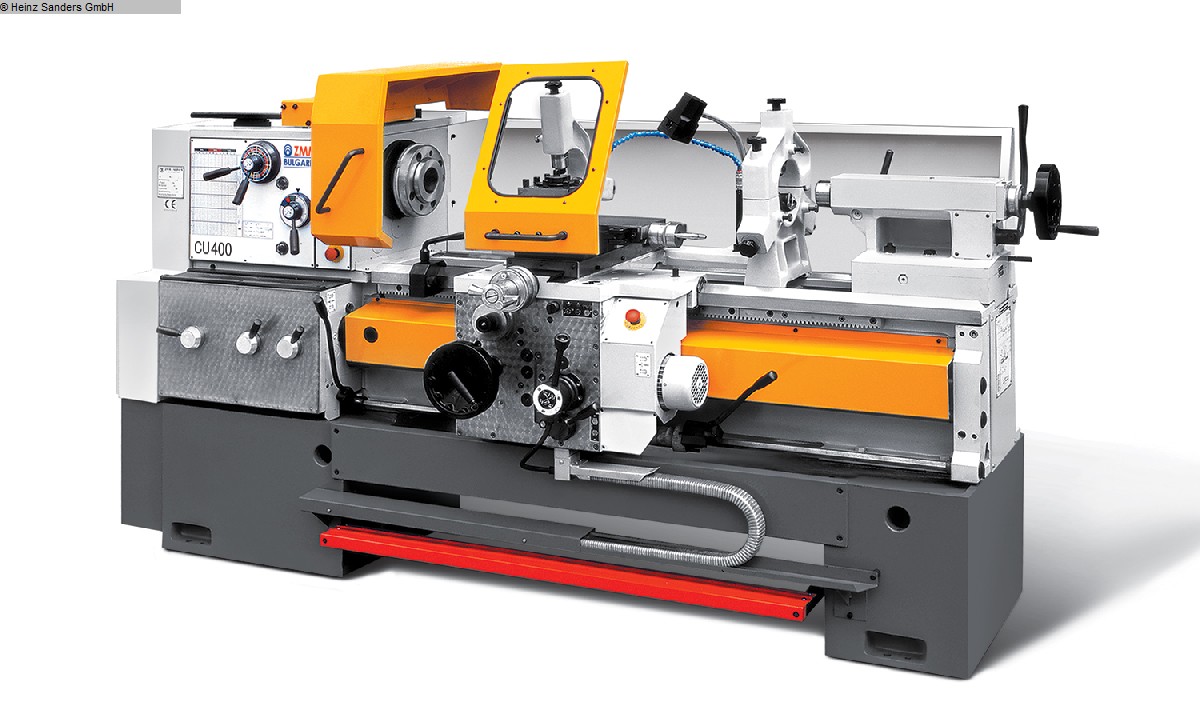

#1125-2200002 · lathe-conventional-electronic

ZMM - CU400/1500 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

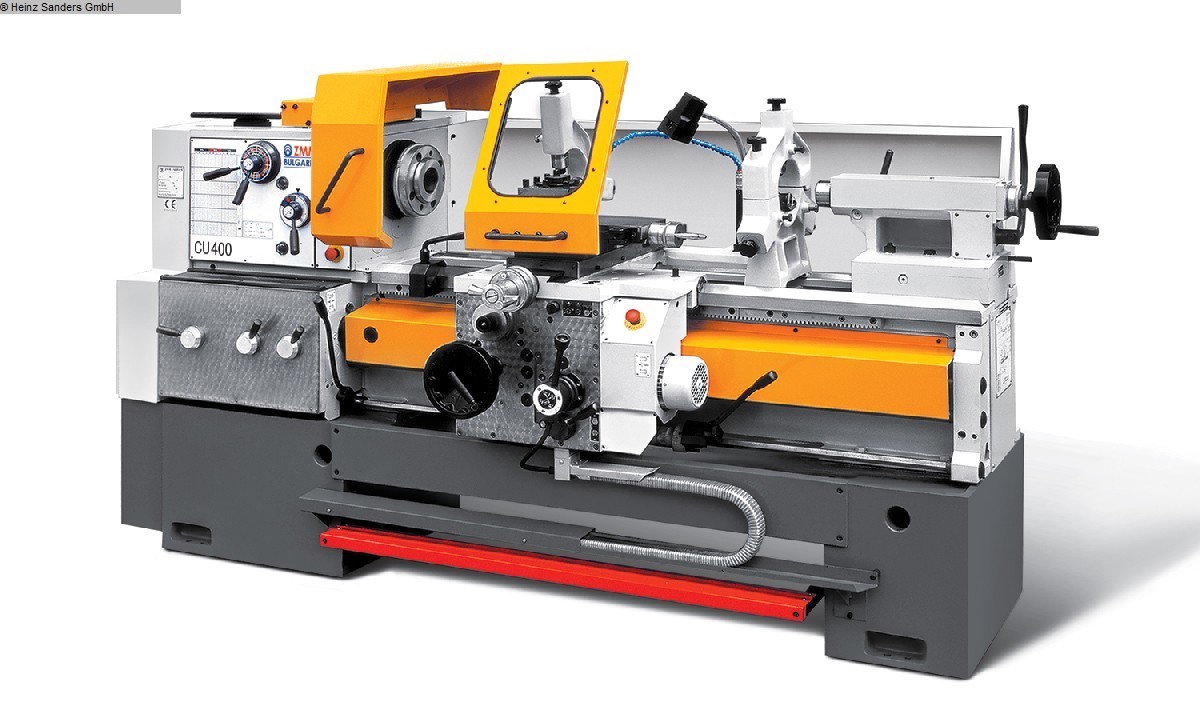

#1125-2200005 · lathe-conventional-electronic

ZMM - CU400/1000 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

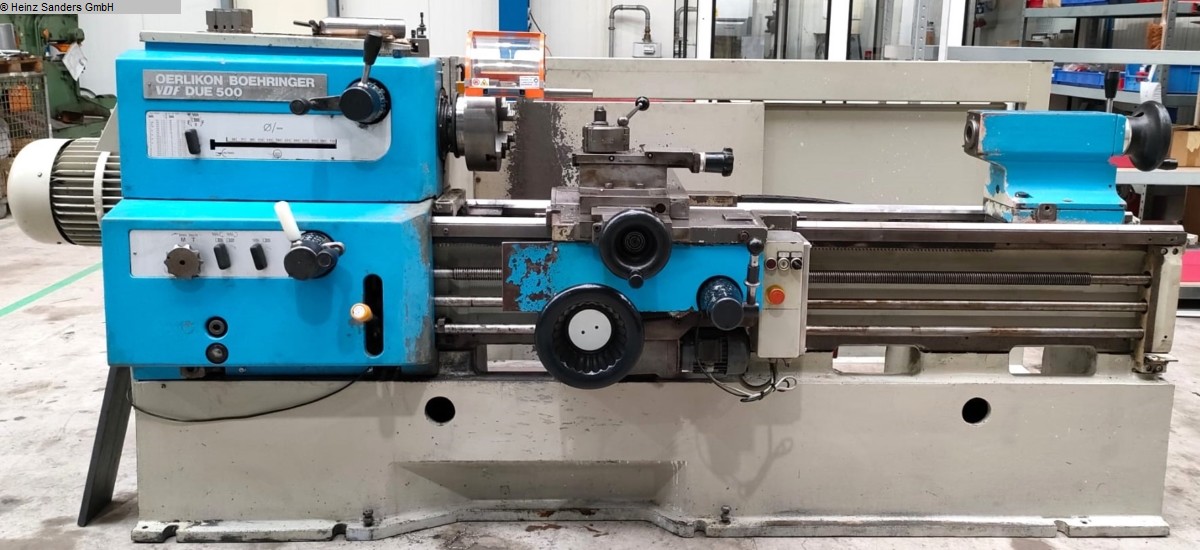

#1125-3200048 · lathe-conventional-electronic

OERLIKON-BOEHRINGER - DUE 500 - - 1985 -

Technical details

- MULTIFIX steel holder - RÖHM 4-jaw chuck Ø250 mm - Lathe chuck protection - Chip protection rear wall

Datasheet

Request / Contact

Bench Drilling Machine

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-3100019 · Bench Drilling Machine

BERNARDO - BM25T 400V - - 2021 -

Technical details

Datasheet

Request / Contact

Jig Boring Machine

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-5955 · Jig Boring Machine

HMB - PBM 1000/60 - - 1996 -

Technical details

CNC plate drilling system HMB PBM1000/60 - W12 for drilling head plates and Base plates in steel construction with tool changer (12x) Number of drilling spindles: 1 pc. Operating Voltage: 220/380V Frequency: 50 Hz Total connection value: 22 kVA

Datasheet

Request / Contact

Pillar Drilling Machine

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-3100001 · Pillar Drilling Machine

FLOTT - SB 14 - - unbekannt -

Technical details

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7189 · Pillar Drilling Machine

ALZMETALL - ALZSTAR 30 iTRONIC - - NEU -

Technical details

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2100025 · Pillar Drilling Machine

IBERDRILL - AZ 34 PSR + Fuessschalter - - NEU -

Technical details

Column drilling machines - V-belt drive with foot switch - Drilling machine of circular column feed automaticmechanical - Drive by electronic wide V-belt - Spindle taper: CM 4 - Stepless speed adjustment with frequency converter - Potentiometer for speed adjustment - digital speed display - Automatic feed reversal when threading - Scale with adjustable drilling depth - automatic tool ejector - Push button for EMERGENCY STOP switch for right/left rotation - Electronic control integrated in the drill head - integrated coolant device - Machine light - height-adjustable chip protection disc with micro switch - fixed table - CE marking

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-8165123 · Pillar Drilling Machine

SBN - SB 45 B - - NEU -

Technical details

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-8165281 · Pillar Drilling Machine

SBN - SB 35 B - - NEU -

Technical details

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2100017 · Pillar Drilling Machine

ALZMETALL - AX 4 iTRONIC - - NEU -

Technical details

** NEW ALZMETALL MODEL RANGE ** 7 "TFT - LCD display with touch function: * Spindle speed setpoint * Actual speed display * Integrated drilling depth display * with touch zero point transfer * Virtual drilling depth scale in the display * Machine status displays and warnings in the display * Service information * Selectable user language: DE / EN / FR / ES / IT / NL / RU. Furnishing: - Thread cutting device * for thread cutting with a stop * max. 6 threads / min (thread cutting performance depends on the spindle speed) * Thread depth adjustable via depth stop * in the TFT - LCD display (3 tools). - automatic spindle feed with feed overload protection - Infinitely variable speed setting by means of an adjusting lever - Spindle protection with electrical fuse - Three separate buttons for clockwise rotation - counterclockwise rotation - stop - Mushroom pushbutton (latching) for EMERGENCY STOP - Main switch, lockable - Right and left rotation by contactor control - Control voltage 24 volts - Protection class IP 54 - Painting: DD textured paint signal white RAL 9003, PANTONE 7545c, black - Machine oil first filling: oil bottle, loose delivery including special accessories: - 12. LED machine light - 24. Coolant system A * in the machine base

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7192 · Pillar Drilling Machine

ALZMETALL - ALZSTAR 40 iTRONIC - V - - NEU -

Technical details

- 7"TFT LCD display with touch function: * Manual input of spindle speed setpoint * Speed display actual value * Integrated drilling depth display with touch zero point transfer * Virtual drilling depth scale in the display * Service information * Selectable user language: DE/EN/FR/ES/IT/NL/RU - Infinitely variable speed setting by means of an adjusting lever - Spindle protection with electrical fuse - Three separate buttons for clockwise rotation - counterclockwise rotation - stop - Mushroom pushbutton (locking) for EMERGENCY STOP - Main switch, lockable - Right and left rotation by contactor control - Control voltage 24 volts, protection class IP54 - Feed overload protection - Machine oil first fill; Oil bottle, loose delivery - Paint finish: DD structure paint signal white RAL 9003, Pantone 7545c, black

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7365 · Pillar Drilling Machine

OPTIdrill - DP 33V Aktions-Set - - NEU -

Technical details

Column drilling machine OPTIdrill DP 33V promotion set / 3020680SET With an electronically controllable drive in a modern design * Industrial engine * Quiet running spindle thanks to new spindle design * Machine operation with safety electronics in 24 V direct current * Guaranteed concentricity = 0.02 mm in the measured drilling spindle * Clockwise/counterclockwise rotation * Precision spindle bore * Control panel with user-friendly, dirt and water resistant * Membrane keyboard * RPM display * Separate emergency stop button * Tapping function * Precisely crafted, stable drill table with diagonal T-slots with all-round cooling water channel, can be tilted sideways by ±45° and rotated by 360° * Drilling depth stop * LED machine light integrated in the drill head * V-belt cover with safety switch * Thick-walled steel column for high power absorption and stability * Solid, large base plate with T-slots * Execution of the entire machine Scope of delivery: - Keyless drill chuck 0 - 16 mm - T-Nuts -expectors - Operating tool - BMP 160 machine vice

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2100020 · Pillar Drilling Machine

HM MACHINERY - SBM 32 F AUT - - NEU -

Technical details

- automatic drill feeds (magnetic clutch) - Height adjustable and angle adjustable table - Movable work table - Integrated cooling system - Powerful engine - 3 hand levers for drilling feed - Safety shield with limit switch - Separate emergency stop - Built-in working lights - Incl. drill chuck 16mm - B16 - Built-in automatic thread cutting.

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-1030 · Pillar Drilling Machine

IBERDRILL - Falken AZ 32 - - NEU -

Technical details

Accesories: -Machine light (built-in) -Coolant device in the foot (built-in)

Datasheet

Request / Contact

Contact Trader

Heinz Sanders GmbH Maschinen - Werkzeuge - Schweisstechnik

Fresenburger Weg 4

49779 - Niederlangen

Deutschland

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50

maschinen@heinz-sanders.de

www.heinz-sanders.de

Contact person:

Frau Christine Fokken +49 (0) 5939 9406 40

Fresenburger Weg 4

49779 - Niederlangen

Deutschland

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50

maschinen@heinz-sanders.de

www.heinz-sanders.de

Contact person:

Frau Christine Fokken +49 (0) 5939 9406 40

Machine category

· Abkantpresse - hydraulisch · Absaugung · Airless- und Farbspritzgerät · Arbeitsbühne · Ausklinkmaschine · Bandschleifmaschine · Bandsäge · Bandsäge - Vertikal · Bearbeitungszentrum · Behälterdrehvorrichtung · Bettfräsmaschine - Universal · Bettfräsmaschine - Vertikal · Biegemaschine horizontal · Blechbiegemaschine - 3 Walzen · Blechrichtmaschinen · Bohrerschleifmaschine · Brennschneidemaschine · Bügelsäge · CNC Drehmaschine · Container · Doppelgehrungssäge · Doppelständerpresse - Hydraulisch · Dornrohrbiegemaschine · Drehmaschine-konventionell-elektronisch · Einständerpresse - Hydraulisch · Entgratmaschine · Fräsmaschine - Universal · Furnier- und Plattensäge · Gabelhubwagen Hand · Gabelstapler · Gewindeschneidmaschine · Gleitschleifanlage · Handhebel-Schere · Handwerkzeuge · Hubwagen - Elektro · Kaltkreissäge · Kehrmaschine · Kettenzug - elektrisch · Kompressoren · Koordinatenbohrmaschine · Laserschneidmaschine · Lochstanze · Messplatte · Nutenfräsmaschine - Vertikal · Nutenziehmaschine · Positionierer · Profilstahlschere - Kombiniert · Punktschweißmaschine · Radialbohrmaschine · Reinigungsanlage · Richtplatte · Ring- Profil- Biegemaschine · Rohrbiegemaschine · Rollenbahnen / Anschlag-Systeme · Sandstrahlanlage · Scherenhubtisch · Schleifmaschinen · Schraubenkompressor · Schweißdrehtisch · Schweißdrehtisch - rund · Schweißroboter · Schweißtisch · Schwenkbiegemaschine · Schwerlastanhänger · Schwerlastregal · Sicken- und Bördelmaschine · Sonstige Lagertechnik · Spannfutter · Spritzgerät · Stromaggregat · Säge- und Bohranlage · Säulenbohrmaschine · Tafelschere - hydraulisch · Tafelschere - mechanisch · Tischbohrmaschine · Transportwagen · Unterstellbock · Vakuum-Lifter · Wasserstrahlschneidanlage · Werkbank · Werkstattpresse - hydraulisch · Werkzeug Voreinstellgerät · Werkzeugfräsmaschine - Universal · Werkzeugschleifmaschine · Werkzeugschrank · WIG-Schweißgerät ·