Welding machines

Machinelist: Welding machines

Plasma Cutting Device

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8459709 · Plasma Cutting Device

JAVAC - AVALON 40.1 AIR - - -

Technical details

Cuts carbon steel, stainless steel, aluminum, copper and more... The air plasma cutting system Avalon 40.1 Air with integrated compressor is Your reliable partner for demanding applications. Run with the Avalon 40.1 Air cuts up to a material thickness of 18 mm. Properties: - IGBT technology - Active PFC technology for high duty cycle and energy efficiency - Manual switch to activate airflow - to set the test air pressure without having to trigger the burner. - Lightweight and compact - Intelligent protection function protects the plasma torch from damage - such as incorrect air pressure, missing consumables, pilot arc overload; Amenities included : - 1x ground cable 3 m - 1x hand cutting torch // PT-60/6 with coaxial cable

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8455053 · Plasma Cutting Device

JAECKLE - PLASMA 60 - - -

Technical details

Description: - Plasma gas: compressed air - Plasma torch with single connection - high frequency ignition - thermal overload protection - very robust and reliable design - The plasma cutting device JÄCKLE Plasma 60 shines with a very good Price-performance ratio. - This plasma cutter is the ideal system for craft, agriculture, Automotive industry etc .; Furnishing: - with burner model P 70/6 mtr.

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8459710 · Plasma Cutting Device

JAVAC - AVALON 65 AIR - - -

Technical details

Cuts carbon steel, stainless steel, aluminum, copper and more... Cutting - clean and reliable. The air plasma cutting system Avalon 65 Air with integrated compressor is your reliable partner for the demanding use. Make slitting cuts up to with the Avalon 65 Air a material thickness of 35 mm. Properties: - IGBT technology - with integrated compressor - Microprocessor control system for excellent and dynamic arcing properties - CNC connection interface - HF-free arc ignition for increased reliability and low EMF exposure - Manual airflow activation switch to test air pressure set without firing the burner - Intelligent protection function protects the plasma torch from damage - such as incorrect air pressure, missing consumables, Pilot arc overload - Mobile system with rollers Amenities included : - 1x ground cable 3 m - 1x hand cutting torch // PT-60/6 with coaxial cable

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8459708 · Plasma Cutting Device

JAVAC - AVALON 40.1 PFC - - -

Technical details

Cuts carbon steel, stainless steel, aluminum, copper and more... The AVALON 40.1 PFC is a light, handy plasma cutting system with high Cutting performance and top cutting quality. Their light weight and ease of use Handling makes them the ideal candidate for trade, workshop and industry. Properties: - IGBT technology - Active PFC technology for high duty cycle and energy efficiency - Manual switch to activate airflow - to set the test air pressure without having to trigger the burner. - Lightweight and compact - Intelligent protection function protects the plasma torch from damage - such as incorrect air pressure, missing consumables, pilot arc overload; Amenities included : - 1x ground cable 3 m - 1x hand cutting torch // PT-60/6 with coaxial cable

Rotary Welding Table

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8531721 · Rotary Welding Table

AK BEND - SRH-1000 - - -

Technical details

he AK BEND SRH hydraulic weld positioner is great for welding, assembly and maintenance work. The positioning is done via a hydraulic turning and tilting function. Description : - hydraulic turning and tilting function - Fast handling of workpieces - Highest productivity through optimal working position - Lifting, tilting and turning of workpieces in one setting - Low non-productive times by turning components - Highest work performance through pleasant working - Back-friendly work for the user Furnishing : - Stepless speed adjustment - free-moving footswitch - Handheld remote control with 5 meter cable - freely movable control panel with digital speed display - analog angle display

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

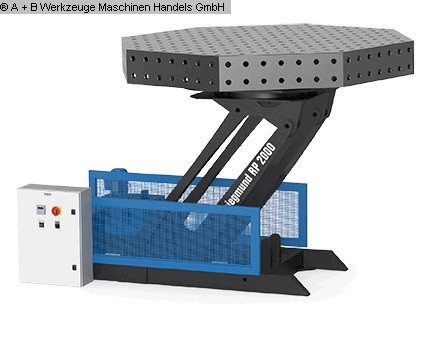

#1008-8531685 · Rotary Welding Table

SIEGMUND - RP 1250 - - -

Technical details

The Siegmund Roto-Positioner is ideal for welding, Assembly and maintenance work. The positioning takes place via a hydraulic one Turn and tilt function. The Siegmund Roto-Positioner is also included equipped with a continuously height-adjustable axis. Furnishing: - Hydraulic rotation of the clamping plate - Tilt range up to 95 ° - Hydraulic height adjustment and tilt function - including hand control

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

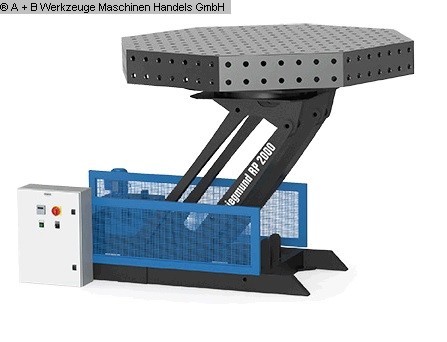

#1008-8531686 · Rotary Welding Table

SIEGMUND - RP 3000 - - -

Technical details

The Siegmund Roto-Positioner is ideal for welding, Assembly and maintenance work. The positioning takes place via a hydraulic one Turn and tilt function. The Siegmund Roto-Positioner is also included equipped with a continuously height-adjustable axis. Furnishing: - Hydraulic rotation of the clamping plate - Tilt range up to 95 ° - Hydraulic height adjustment and tilt function - including hand control

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8459011 · Rotary Welding Table

MB - ECO-S300 - - -

Technical details

Furnishing: - The table can be tilted and clamped at an angle of 0 ° to 90 ° - manual tilting - Start / stop via location-independent foot switch - Direction of rotation can be selected right / left - Adjustable rotation time - The control of the welding machine via control - 350 amp ground connection Scope of delivery: - control (integrated) - foot switch

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-845900 · Rotary Welding Table

MB - PRO 1 - - -

Technical details

Furnishing: - Precise drive unit with face plate, on a stable floor stand. - clockwise / counterclockwise - 2 speed series, stepless - Swivel range from 0 ° - 90 °. Manual tilt - DC gear motor with worm gear, infinitely variable. - diameter of 300 mm. Chrome-plated surface to protect against weld spatter. - The device's control panel is easy to understand and use. - Start / stop via a location-independent foot switch. - The speed and direction of rotation are set on the machine. - HF protected. Scope of delivery: - control (integrated) - foot switch

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-845905 · Rotary Welding Table

MB - POS-1TW - - -

Technical details

For heavy industry When choosing a turntable, it is essential Turning and tilting torque must be taken into account. To note applies to how far the center of gravity of the workpiece is from the The faceplate is away or how far the center of gravity is is eccentric from the center. By means of a Rotary and tilting tables can be used to optimize workpieces position for welding. - Robust construction. - Infinitely variable. - Hand remote control. - HF protected. Furnishing : - 1 control (integrated) - 1 wired remote control

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-845902 · Rotary Welding Table

MB - PRO 3 COM 1000 - - -

Technical details

Furnishing: - The table can be tilted and clamped at an angle of 0 to 90 - Start / stop via a location-independent foot switch. - Direction of rotation can be selected right / left. - Adjustable rotation time. - The turntable has a 60 mm hollow shaft. - The turntable has a diameter of 340 mm. The surface is chrome-plated for Protection against welding spatter. - The table speed is adjustable from 0.6 - 6 rpm. - The control of the welding machine via the turntable control is possible. - The ground contact transmits 300 A / 100%. - The turntable and the control are separate. - HF protected. - Operating instructions in German Functions of the COM 1000 control: - Right / left rotation - stepless speed control - welding torch on / off - Control for turning time

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8459010 · Rotary Welding Table

MB - PRO 2 COM 1802 - - -

Technical details

Furnishing: - The table can be adjusted at an angle of 0 to 90 degrees tilt and jam - Start / stop via a location-independent foot switch. - Direction of rotation can be selected right / left. - Adjustable rotation time - The turntable has a 60 mm hollow shaft - The turntable has a diameter of 340 mm. The surface is chrome-plated for Protection against welding spatter. - The table speed is adjustable from 0.6 - 6 rpm. - The control of the welding machine via the turntable control is possible. - The ground contact transmits 300 A / 100%. - The turntable and the control are separate. - HF protected. - COM 1800 control with lap welding - Operating instructions in German Functions COM 1800 control: - Right/left rotation - Infinitely variable speed control - Welding torch on/off - Overlap welding adjustable - Controller for rotation time (2-stroke / 4-stroke) - Speed display

Spot Welding Machine

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9451131 · Spot Welding Machine

TECNA - 4602 N - - 1997 -

Technical details

Furnishing: - Spot welding machine from a training workshop - Welding control TE 90 Mark II Welding control TE 90 is a microprocessor control for single-phase resistance welding machines. The welding controller has the task of To control machine elements, especially the SCR, which controls the adjustment of the control the welding current. The duty cycle that the TE 90 performs is described using the programming parameters. - SCR synchronous control, welding time regulation by phase cut - Simple programming via 4 buttons - Current rise and pulses - Single point and automatic - Secondary current compensation for welding dirty metal sheets and wires - Welding time lock optimizes current draw from the mains - Solenoid valve 24 Vdc 7.2 W max. with output protected against short circuits * Machine link : http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9451131

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9451132 · Spot Welding Machine

TECNA - 3402 N - - 1994 -

Technical details

Furnishing: - Spot welding machine from a training workshop - Welding control TE 90 Mark II Welding control TE 90 is a microprocessor control for single-phase Resistance welding machines. The welding control has the task of: To control machine elements, especially the SCR, which controls the setting of the Control welding current. The duty cycle that the TE 90 performs is described using the programming parameters. - Synchronous control SCR, welding time regulation by phase cut - Easy programming via 4 buttons - Current surge and pulsing - Single point and automatic - Compensation of the secondary current for welding dirty metal sheets and wires - Welding time locking optimizes power consumption from the mains - Solenoid valve 24 Vdc 7.2 W max. with short-circuit protected output * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9451132

Welding Smoke Suction

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9451130 · Welding Smoke Suction

KEMPER - 82302 - - 2011 -

Technical details

The "KEMPER mobile cartridge filter" is designed for the extraction of pollutants that arise during the various electric welding processes. In principle, the device can be used in all work processes in which particulate pollutants, i.e. smoke and dust, are released. However, you should make sure that no "rain of sparks" (e.g. from a grinding process) is sucked into the filter device. Furnishing : - Mobile welding fume extraction or mobile cartridge filter - Suction without suction hose - User manual + wiring diagram (PDF) * Machine link : http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9451130

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8459706 · Welding Smoke Suction

FILTOO - SIG 230 / BGIA - - -

Technical details

Description: The filtoo filter device newly developed by TEKA is a mobile filter system that many Tasks in the field of filtration of Smoking, dusts and gases can be used. Also suitable for high-alloy steels (stainless steel). (the device was based on DIN EN ISO 15012-1 (2005) tested and is IFA (formerly BGIA) certified (IFA No. 201020469/1140) for welding smoke class "W3" (degree of separation:> 99.9%)) Where can the SIG 230 filtoo be used? - at welding workplaces - in the workshop area - for soldering applications - with restorers - in locksmiths Furnishing: - BGIA - certified suction and filter system IFA 1005030 for suction to hochleg. Steels & non-ferrous metals - Operating instructions in German optional equipment for a surcharge (recommended) - Retrofit kit STAVO (dust pre-separation) - for FILTOO with spark protection and collecting tray Note : - The device is only used to extract dry dust / smoke - Read the operating instructions before using for the first time

Welding Unit

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8455055 · Welding Unit

LORCH - MIG MAG M 304 *SET* - - -

Technical details

** LORCH authorized trader - other models on request Description: Automatic setting With the help of the automatic adjustment of the wire feed speed The Lorch M 304 supports you with the selected voltage level Finding the perfect working point. Quality wire feeder The Lorch M 304 comes with a 4-roller wire feed as standard Robust housing due to its compact and robust You can easily place your Lorch M 304 under the housing with sturdy wheels Stow away the workbench or use the top of the machine as a storage area. Double gas bottle lock For optimal safety, the Lorch M series has a double Gas bottle lock. So you can move your power source safely. Furnishing: - Integrated 4-roll wire feed - ML2500 burner, 4m - Workpiece lead 25 mm² - Pressure reducer with volume and content manometer - gas hose - Basket spool adapter K300 - Mains cable with CEE-16 plug - Manual

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8455052 · Welding Unit

LORCH - MicorMIG 300 BasicPlus - - -

Technical details

** LORCH authorized trader - other models on request Description: - A MIG-MAG system that can also use electrodes. Simply remove the burner, Connect the electrode holder to the additional electrode socket and Select electrode welding in the control panel. Furnishing: - Compact device, gas-cooled with synergy operation - stepless welding current setting - Volt & ampere indicator - 7-stage arc dynamic control - Synergy control - Welding program selection in the feed area - full upgradeability

Trader Profile: A + B Werkzeuge Maschinen Handels GmbH

Contact Trader

Rottweg 17

48683 - Ahaus

Deutschland

(0049)-2561-9384-71">(0049)-2561-9384-71

(0049)-2561-9384-36

info@ab-maschinen.de

www.ab-maschinen.de

Profile of Trader

Welding is process which involves the joining of two materials through the use of a combination of heat and pressure. Depending on the type, shape and size of the materials being welded, different types of welding machines can be employed to achieve the desired result. Arc welding, gas welding and resistance welding are amongst the most popular methods in use today. Finding the right welding machines for the job is as simple as a trip to LagerMaschinen, your online marketplace for used machinery.

Find the best welding machines at LagerMaschinenWelding is a popular method for creating strong, durable bonds in both metals and thermoplastics. Its popular amongst home hobbyists and industry professionals alike. Depending on the nature of your project, a wide variety of welding machines are available to help you achieve the desired outcome. Whether you perform manual metal arc welding (mma) or spot welding, you can find used machines for your welding projects quickly and easily online at LagerMaschinen, your best source for used industrial equipment.

Shopping online for used machines is easier than everSmart shoppers recognize the value of both time and money in todays fast-paced society. Maximizing these important resources can be a challenging task, but it doesnt have to be. Shopping online for used machines is a practical solution for those with busy schedules and limited budgets. From welding machines to drills, presses and grinders, LagerMaschinen is the best place to find the high-quality used machines for your home workshop or business at prices you can afford.

TOP Manufacturer:

SIEGMUND - DUMETA - WMT - GERD WOLFF - - HISWELD - UWM - WELDING - SIEGMUND - ZUBEHOER - ESAB -

Rottweg 17

Contact Trader

Rottweg 17

48683 - Ahaus

Deutschland

(0049)-2561-9384-71

(0049)-2561-9384-36

info@ab-maschinen.de

www.ab-maschinen.de

Contact person:

* über 500 Maschinen lagernd -

Gerne führen wir Ihnen Ihre gewünschte Maschine unter Strom vor *