Suction

Machinelist: Suction

Pillar Type Swivelling Crane

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-06328 · Pillar Type Swivelling Crane

DEMAG - D-MOS 360 - - 2010 -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03720 · Pillar Type Swivelling Crane

PFEIFER - PSE350x5500 - - 1997 -

Technical details

K9F 0902 The techn. Information is provided by the manufacturer or operator and is therefore non-binding. We reserve the right to prior sale; Our terms of sale apply exclusively. About us More than 400 of our own machines in the warehouse More than 12,000 m² of storage space, crane capacity 70 t More than 1000 items Accessories for your workshop If you want to sell machines, systems or your company, then contact us.

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-04956 · Pillar Type Swivelling Crane

ABUS - A1 - - 1990 -

Technical details

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Please note: The machine is dismantled and ready for loading. It is not possible to show it under power or make a video. Our offer includes already the best pictures. So we don’t have and won’t send additional pictures. ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-05422 · Pillar Type Swivelling Crane

DEMAG - XXX - - 1988 -

Technical details

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Please note: The machine is dismantled and ready for loading. It is not possible to show it under power or make a video. Our offer includes already the best pictures. So we don’t have and won’t send additional pictures. ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-05956 · Pillar Type Swivelling Crane

ABUS - A 2 - - 1988 -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03719 · Pillar Type Swivelling Crane

Abus - VS - - 1987 -

Technical details

K9F 0902 The techn. Information is provided by the manufacturer or operator and is therefore non-binding. We reserve the right to prior sale; Our terms of sale apply exclusively. About us More than 400 of our own machines in the warehouse More than 12,000 m² of storage space, crane capacity 70 t More than 1000 items Accessories for your workshop If you want to sell machines, systems or your company, then contact us.

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03782 · Pillar Type Swivelling Crane

Demag - K02-Sk01 - - 1986 -

Technical details

K9F 0902 The techn. Information is provided by the manufacturer or operator and is therefore non-binding. We reserve the right to prior sale; Our terms of sale apply exclusively. About us More than 400 of our own machines in the warehouse More than 12,000 m² of storage space, crane capacity 70 t More than 1000 items Accessories for your workshop If you want to sell machines, systems or your company, then contact us.

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03527 · Pillar Type Swivelling Crane

DEMAG - 500kg - - 1976 -

Technical details

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8531890 · Pillar Type Swivelling Crane

ABUS - Säulenschwenkkran LS - - -

Technical details

Description: - Trolley power supply - Trailing cable, cable slack approx. 800 mm - Operation from the hallway using a pendant control including: - ABUS electric chain hoist - Chain hoist type GM 4 1000.5-2, 2-leg - painted in color RAL 5017 traffic blue - Load capacity 1 t - hook path 3000 mm - highest hook position 2442 mm - Calculation basis FEM 9.901 - Drive group 2m / M5 - Lifting, 2-stage (pole switchable) 1.3 / 5 m / min - Lifting capacity 0.22 / 0.9 kW - duty cycle 60% ED - Circuits 360 c / h Overload protection The crane system complies with the requirements of the Machinery Directive 2006/ 42 / EC as well as the currently valid UV regulations DGUV regulation 52 (formerly BGV D6). included : - Anchor rods L200 (set) size LS 200 - Consists of 8 pieces M27 mm x 800 mm with 1 steel template (500/8) - for fixing the foundation, including accessories for grouting There is an assembly gap between the column base to align the slewing crane and building floor to be provided. The assembly gap is after approx. 4 weeks Crane operation to be poured under by the customer. ** Fig. Shows a similar crane system

Datasheet

Request / Contact

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8531778 · Pillar Type Swivelling Crane

ABUS - Säulenschwenkkran LS - - -

Technical details

Description: - Load capacity 250 kg - projection 4000 mm - Construction height 4025 mm - Crane lacquer in color RAL 1007 daffodil yellow - Calculation basis DIN 15018 - Crane classification H2 / B2 - Operating location hall operation - Size / bracket profile LS36 / FormC 110x90 - Height of the lower edge of the boom 3425 mm - Operating voltage 3 / PE ~ 50 Hz 400 V - Direct control type of control - Degree of protection IP55 - Swivel range, nominally 270 ° - Panning by hand including: - Anchor rods size LS 36 - Consists of 8 pieces M24 mm x 800 mm, with 1 steel template (420/8) for - Fastening to the foundation, including accessories Electric chain hoist: - Chain hoist type GM 2 250.6-1, 1-leg - painted in color RAL 5017 - traffic blue - Load capacity 250 kg - hook path 4000 mm - highest hook position 3034 mm - Calculation basis FEM 9.901 - Drive group 2m / M5 - Lifting, 2-stage (pole switchable) 1.5 / 6 m / min - Lifting power 0.09 / 0.35 kW - duty cycle 60% ED ** Fig. Shows a similar crane system

Datasheet

Request / Contact

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8531889 · Pillar Type Swivelling Crane

ABUS - Säulenschwenkkran LS - - -

Technical details

Description: - Trolley power supply - Trailing cable, cable slack approx. 800 mm - Operation from the hallway using a pendant control including: - ABUS electric chain hoist - Chain hoist type GM 2 500.4-2, 2-leg - painted i color RAL 5017 traffic blue - load capacity 500 kg - hook path 3000 mm - highest hook position 2965 mm - Calculation basis FEM 9.901 - Drive group 2m / M5 - Lifting, 2-stage (pole switchable) 1/4 m / min - Lifting power 0.09 / 0.35 kW - duty cycle 60% ED - Circuits 360 c / h Overload protection The crane system complies with the requirements of the Machinery Directive 2006/ 42 / EC as well as the currently valid UV regulations DGUV regulation 52 (formerly BGV D6). included : - Anchor rods L200 (set) size LS 200 - Consists of 8 pieces M27 mm x 800 mm with 1 steel template (500/8) - for fixing the foundation, including accessories for grouting There is an assembly gap between the column base to align the slewing crane and building floor to be provided. The assembly gap is after approx. 4 weeks Crane operation to be poured under by the customer. ** Fig. Shows a similar crane system

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03525 · Pillar Type Swivelling Crane

DEMAG - - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03535 · Pillar Type Swivelling Crane

DEMAG - 500kg - - -

Technical details

Suction

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24029 · Suction

INDUSTAR - 1N80A2 - - UNBEKANNT -

Technical details

Datasheet

Request / Contact

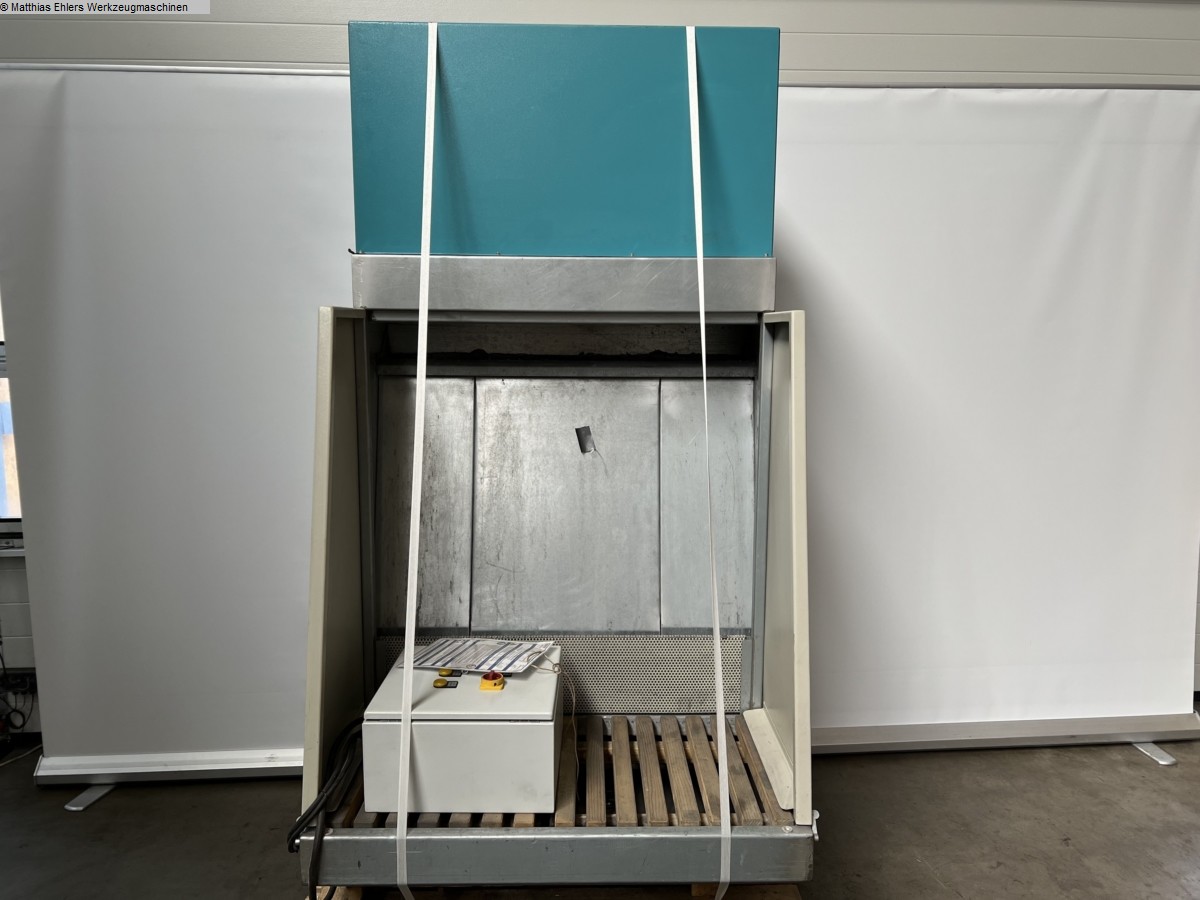

- Matthias Ehlers Werkzeugmaschinen

- Nikolaus-Otto-Straße 19 + 21

- 22946 Trittau

- Deutschland

-

+49 (0)4154 - 986 99 12

+49 (0)4154 - 986 99 14 -

anfrage@ehlers-wzm.de

www.ehlers-wzm.de

#2033-2023247 · Suction

TECHNO-JET - 4MD - - unbekannt -

Technical details

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2810012 · Suction

TEKA - Cartmaster - - NEU -

Technical details

- Hose arm 3 m, joints inside - Filter cartridge: dust class M - Pre-filter: baffle plate - Current type: 3Ph+N+PE The filter system --------------------------------------- The mobile filter system of the Cartmaster IFA type is thanks to the automatic Cleaning particularly suitable for welding work with unalloyed and alloyed steels, galvanized material and aluminum with heavy smoke development. It corresponds to the safety requirements for devices Welding fume class "W3" (high-alloy steels with alloy components > 30% Nickel-based alloy).If used as intended, the system can be used for the Recirculation mode used because the requirements for the Exceptions according to TRGS 560 are fulfilled. That special developed, dirt-dependent cleaning system ensures a good cleaning behavior of the filter cartridge, so that an optimal suction performance is guaranteed throughout the operation. The cleaned particles fall into a dust collection drawer from which they can then be disposed of. The powerful spiral fan ensures even with saturated Filter cartridges for a high volume flow. The filter media --------------------------------------- A baffle serves as a pre-separator for coarse particles. The filter cartridge installed below (dust class M, degree of separation > 99%) filters the finest smoke and dust particles. The cartridge is factory coated which increases the service life. The extraction arm ------------------------ The extraction arm can be moved with the 3 internal joints Position spring support slightly and is in the set position cantilevered. A throttle flap integrated in the extraction hood enables the Flow rate setting.

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-8366978 · Suction

TEKA - filtoo 1,1 kW 1x3 mtr. - - NEU -

Technical details

Particle pre-separator: coarse filter, pre-filter Main particle separator: main filter Gas separator: activated carbon filter Hose arm: joints inside What is the filtoo? The filtoo filter device newly developed by TEKA is a mobile filter system, for many tasks in the area of ??filtration of smoke and dust and gases can be used. The device was based on DIN EN ISO 15012-1 (2005) tested and is IFA (formerly BGIA) certified (IFA No. 201020469/1140) for welding smoke class "W3" (degree of separation:> 99.9%). at The filtoo is intended to be used for the separation of smoke suitable, which by welding separation and joining processes at the Machining of unalloyed steels, including high-alloy chrome / Nickel steels are released. How does the filtoo work? The Polluted air sucked into the filter system. In a multi-level The filter process filters the particles / gases from the air stream and the clean air is fed back into the work area. Where can the filtoo be used? At welding workplaces, in the workshop area, for soldering applications, at Restorers and locksmiths. What do you get for your money? All you get is a completely ready-to-use "plug and play system" the recording device must be connected before commissioning. How is the filtoo set up? The housing is made of a stable sheet steel construction and is inside as well as provided with a powder coating on the outside. The filter elements are over A maintenance hatch is accessible and can therefore be accessed very easily and quickly can be removed. The system has functional controls.

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7227 · Suction

NOVUS - Airtower FT 20.000 - - NEU -

Technical details

Modular plug & play airtower for hall extraction of welding fumes with integrated, soundproofed Fan, automatic, differential pressure controlled Filter cleaning, system control with color display, particle pre-separation and IFA - tested filter cartridges. The system is for a volume flow of average 20,000 m³ / h designed 1st filter stage - main filter: Filter area: 222 m² Number of filters: 6 pieces Dust class according to DIN EN 60335-2-69: M. Degree of separation:> 99.9% Cleaning: Jet - Pulse Compressed air connection: NW 7.2 mm, 4-6 bar, oil and water free 2nd filter stage - fine dust filter. Filter area: 65 m² Filter class according to ISO 16890: ISO ePM1 80% 3rd filter stage - Synthetic fiber mats: Filter area: 8 m² Filter class according to ISO 16890: ISO coarse 60% Total filter area: 295 m² Dimensions: Width filter unit: 2,066 mm Depth filter unit: 1,756 mm Height of filter unit: 3,643 mm Dust container: 200 liters Version Sanders incl .: - NOVUS efficiency package FT20.000 - timer - NOVUS particle sensor

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2810013 · Suction

TEKA - StrongMaster IFA - - NEU -

Technical details

mobile extraction, welding fume extraction (manual cleaning by loss of pressure) - Hose arm 3 m, joints inside - Filter cartridge: dust class M - Particle pre-separator: baffle plate - Current type: 3Ph+N+PE The filter system --------------------------------------- The mobile filter system of the type StrongMaster IFA is particularly suitable for Welding work with unalloyed and alloyed steels, galvanized material and Aluminum in case of heavy smoke development. She corresponds to the Safety requirements for devices in the welding fume class "W3" (high-alloy steels with alloy components > 30% nickel-based alloy). When used as intended, the system can be used for be used in the recirculation mode, since the requirements for the Exceptions according to TRGS 560 are fulfilled. The filter will via a maintenance door using a compressed air gun from the clean air side cleaned. The cleaned particles fall into a dust collection drawer from the they can then be disposed of. The powerful scroll fan ensures a high volume flow even with saturated filter cartridges. The filter media --------------------------------------- A baffle serves as a pre-separator for coarse particles. The filter cartridge installed below (dust class M, degree of separation > 99%) filters the finest smoke and dust particles. The cartridge is factory coated which increases the service life. The extraction arm ------------------------ The extraction arm can be moved with the 3 internal joints Position spring support slightly and is in the set position cantilevered. A throttle flap integrated in the extraction hood enables the Flow rate setting.

- Matthias Ehlers Werkzeugmaschinen

- Nikolaus-Otto-Straße 19 + 21

- 22946 Trittau

- Deutschland

-

+49 (0)4154 - 986 99 12

+49 (0)4154 - 986 99 14 -

anfrage@ehlers-wzm.de

www.ehlers-wzm.de

#2033-2023081 · Suction

HEAB - HAL-1 / BEAL - 100/50 - - 2018 -

Technical details

In our opinion, the machine is in very good condition and can be viewed by appointment. ***Accessories, tools and clamping devices shown are only part of the scope of delivery if this is noted in the additional information.*** *** Changes and errors in the specifications and information, as well Subject to prior sale! ***

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-Z01052 · Suction

TEKA - 792SAD - - 2011 -

Technical details

Sweat extractionThe techn. Data are manufacturer or operator information and therefore non-binding. We reserve the right to prior sale; Our terms and conditions of sale apply exclusively.About usMore than 400 of our own machines in the warehouseMore than 12,000 m² of storage space, crane capacity 70 tMore than 1000 items Accessories for your workshopYou want to sell machines, production lines or your company,then contact us.

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-3810005 · Suction

TEKA - WNA 7500 A - - 2011 -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-Z01062 · Suction

Donaldson - Tovit DCE Top 450 - - 2003 -

Technical details

Sweat extractionThe techn. Data are manufacturer or operator information and therefore non-binding. We reserve the right to prior sale; Our terms and conditions of sale apply exclusively.About usMore than 400 of our own machines in the warehouseMore than 12,000 m² of storage space, crane capacity 70 tMore than 1000 items Accessories for your workshopYou want to sell machines, production lines or your company,then contact us.

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-05980 · Suction

KEMPER - System 5000 - - 2000 -

Technical details

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Please note: The machine is dismantled and ready for loading. It is not possible to show it under power or make a video. Our offer includes already the best pictures. So we don’t have and won’t send additional pictures. ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

- 1

- 2

TOP Manufacturer:

TEKA - KEMPER - LINCOLN ELECTRONIC - ABSOLENT - ALKO - VENTI OELDE - HEAB - UNBEKANNT - OPITZ - INDUSTAR -