Assembling station

Machinelist: Assembling station

Assembling station

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5721 · Assembling station

RUCHSER - Holzfenster-Fertigung Montage - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5916 · Assembling station

RUCHSER - RU-S1 - - neu -

Technical details

Assembly glazing and sealing stand with lifting device ************************************************** ***************************** RU -S1 Stop - and assembly table standing, length 2000 mm, width 700 mm Plant height 1600 mm, lifting device with pneumatic 300-1000 mm, Space than roller conveyor , roll length 200 mm, roller pitch 200mm. Roller conveyor height adjustable 280-350 mm. Contact surface with Felt strips and a height-adjustable rubber roller bar at the bottom to Top . Conditioning grille to protect the edges , left and right respectively one Role as edge protection for elements up to 2500 mm height. Aufstellrollenbahn with steel rollers , roll length 200 mm, roller spacing 200 mm, 2 shelf boards, load capacity 300 kg. alternatively : ------------- RU -S2 Stop and assembly table standing . Same as RU -S1 However, length 3000 mm alternatively : ------------ RU- S3 Stop and assembly table standing design as RU -S1 However, length 4000 mm (technical details according to manufacturer - without guarantee ! ) Prices on request!

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2658 · Assembling station

RUCHSER - RU-MKS-1,4 Montage-Kipptisch - - neu -

Technical details

RUCHSER assembly tilting table RU-MKS 1,4 --------------------------------------- Universally applicable work table e.g. for frame assembly, roller shutter box assembly, bars, sash fittings, glazing Equipment of machine, alternative / optional equipment on request! Pos. 1.0: Article no .: 8820000 RU-MKS-1,4 assembly tilting table Basic dimensions 1400 x 1750 mm, extended 3400 x 2500 mm Support surface with 3 support bars, 2 of which are adjustable, one permanently mounted on the upper extension, covered with felt. Support surface with width and Height / depth pull-out. Pneumatic tilting device, Payload 130 kg. Actuation via foot valve. Roller conveyor can be folded down manually and pulled out to the side from 1400-2500 mm, roll length 140 mm closed. Roller conveyor height in vertical Table position adjustable from 300-380 mm, Horizontal working height adjustable from 920-970 mm. ! For security reasons, at least one Flat clamping cylinders can also be ordered! Pos. 1.1: Article no .: 5582 Pneumatic swivel device of the roller conveyor for MKS Pos. 1.2: Article no .: 21127 Support beam 1400mm not extendable for RU-MKS Pos. 1.3: Article no .: 5585 360 ° rotating device with pneumatic locking in 180 ° steps Rotary brake with double-sided actuation When using the rotating device, the minimum roller conveyor height of the increases MKS tables on 330mm Pos. 1.4: Article no .: 6455-01 6 pieces of storage boxes with 2 compartments each, swivel mounted; for RU-MKS Pos. 1.5: Article no .: 5597-10 Driving device for semicircular rails for RU-MKS-P4 Actuation via foot valve, mounted on the roller conveyor side. Pos. 1.6: Article no .: 6354-6 3 double meter semicircular runways 30 x 10 mm. Pos. 1.7: Article no .: 5193-1 Flat clamping cylinder with manual valve, clamping range 130 mm, can be hidden attached to the support beam, with felt on the system part, Attachment left or right Please specify. Item 1.8: Article no .: 5584 Lifting device 450 mm for working on the vertical element. Actuation via foot valve. Maximum payload 200 kg for RU-MKS ...- 1.4 and 140 kg for RU-MKS ...- 2. Item 99.1 Packaging on a pallet --------------------------------------- Total price in this version: on request! See attached video and PDF brochure. (Technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5599 · Assembling station

RUCHSER - Holzfenster-Fertigung Montage - - neu -

Technical details

In addition to standing a PDF document, see the description of positions - Prices on request! RUCHSER standard offer with layout for a wooden window production with being milled Glass bar and screwed corner joints. Daily capacity approximately 15 Window Manufacturing consisting of: Item 1.0 - Item 107 850 000 RU-PWD-H1600/130/4 profile carriage double-sided ************************************************** **** Length 1600 mm, width 850 mm, height 2140 mm for horizontal position round and transport of Profile sections. 12 support arms each column welded to the column, 2 adjustable center column, clear spacing of the support arms 130 mm, Depth of the support arms on each side 400 mm, Support arms covered with felt, with 4 plastic swivel castors, diameter 150 mm, of which 2 with stop means. Item 2.0 - Item 0150001 RU-M rotation - tilting table ************************** manually tiltable bearing surface 1300 x 1400 mm, with 4 plug extension 1000 mm long, including tool tray without weatherboard- ausspaarung. Item 2.1 - Item 5009-1 2 trays with 2 drawers ************************************* (for RU-4, RU-2/4) Item 2.2 - Item 5062-1 Extract left and right ********************************* 500 mm and up to 7000 mm folded down with one support leg Item 2.2 - Item 5012-1 Hinged extension tubes ************************************** Length 700 mm (max. 3 pairs) Item 2.4 - Item 6125-2 Corner mounting fixture ****************************** AoE attacks rectangular pneumatic lowered with clamping unit for 2 profiles mounted on RU-M Item 2.5 - Item 2069-1 tilting ***************** instead of manually, pneumatically operated Item 3.0 - Article 10.782 million RU-EW-2S two-sided vehicles in stock *************************************** Storage capacity max. 36 piece sash L - shaped screw, length 1200 mm, Depth 800 mm, height 2200 mm, edition of Holme felted, 4 swivel castors, 2 with brakes Item 4.0 - Item 6600000 RU-KWI-1000 Commission cart *************************************** unladen be nested, Length 1120 mm, width 1100 mm, working width 850 mm, height 1900 mm, Plant height 1500 mm, bearing capacity 750 kg mobile on 4 plastic castors, Diameter 150 mm, 2 with Stop device, 2 drawers on the left and right each 350 mm in length, max. 1800 mm and Height max. 2100 mm Item 5.0 - Item 740-300 RU-DH-F2 double reel cart for 2 rolls ************************************************** to roll size 620 x 350 mm (without coil) to roll size 800 x 350 mm (with coil) with 4 swivel castors, 2 with stop device Item 5.0a alternative to Item 5.0 - Item 744-200 RU-DH-F4, double coiler car for 4 wheels ************************************************** ***** to roll size 620 x 350 mm (without coil) to roll size 800 x 350 mm (with coil) with 4 swivel castors, 2 with stop device Item 6.0 - Article 7.36 million RU-BW-1200-fog Cart ********************************** with 16 divisions, length 1200 mm, Width 700 mm, height 1100 mm, with 2 shelves, mobile on 4 Plastic castors with a Diameter of 125 mm, 2 with stopper Item 7.0 - Article 10.0092 million RU-FMOG / K wing mounting rotary tilting table ************************************************** * for wings with attached bar and milled glass Bolt on corner joint. Rotary-tilting table with pneumatic tilting device and 6 piece sliding vacuum suction cups. Adjustment range in width from 450-900 mm, in the amount of 320-1600 mm. Telescopic rods for the vacuum suction to 80 mm extended with felt, for supporting of the profiles, roller conveyor with lifting device. When tilted from the horizontal to the vertical position lowers the roller conveyor automatically from the profile thickness. After the Releasing the vacuum suction moves the roller conveyor back to the basic position. PVC rolls, Roll length 100 mm, roller pitch 150 mm, Vacuum generation by Venturi silenced Item 8.0 - Item 10472002 RU-TFW-800/90 wing and door specialist cars ************************************************** ** 10 compartments, compartment distance 90 mm, with half Compartment separator, part of the plant covered with felt, erecting surface with PVC rollers Shelf depth 800 mm, compartment height 2450 mm, Height 2750 mm, width 1350 mm. Mobile on 4 plastic castors, Diameter 150 mm, 2 with brake facility. Brake means for holding the elements in the Transport. About an eccentric, the elements are raised on one side. Item 8.1 - Item 6559 guide rollers ************************** 1 pair Item 8.2 - Item 6340 1 guide rail 2500 mm long *************************************** Item 9.0 - Item 0.98 million RU-SW1-90 ° vertical work table ***************************************** for weather protection leg Fri 03:05:10 10 mm offset. Wooden windows with turning device for Glazing and double-sided sealing, Angle length 1500 mm, opening angle 90 ° max., Working width 2500 mm, Overall length 1700 mm, overall width 700 mm, height 1600 mm plant, plant- surface with felt the side of the plant part on the insertion side a role as Edge protection for elements up to 2500 mm Height, pneumatic lifting device von 300 - 1000 mm Item 10.0 - Article 10,799,001 RU-FLG 280/9 flood and painting hangers ********************************************** for the color treatment of the wing and Frame profiles, horizontal positioning or inclined approximately 30 °. 9 pairs of arbors 100 mm long, at an angle of 45 ° spacing the spikes in height 180 mm, distance in width 280 mm, hole spacing for the Holes on the frame profile 320 mm, Diameter 12 mm, height 2200 mm, as a function of the suspension hooks adapted to the existing monorail Total price of this placement: Place order! (technical details according to manufacturer - without guarantee!)

Datasheet

Request / Contact

Boring and dowel inserting machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

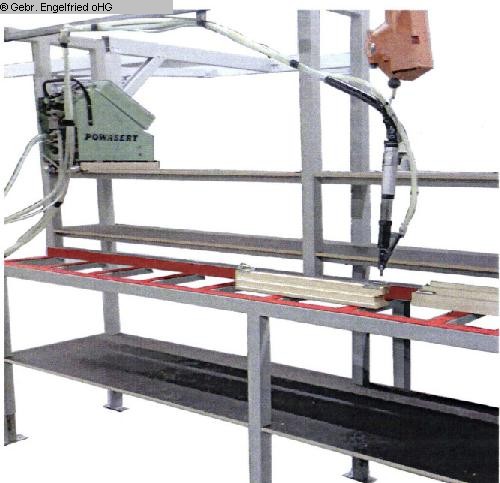

#1305-5710 · Boring and dowel inserting machine

GÖTZINGER - BLE - Video - - - neu -

Technical details

1 Götzinger dowel gluing and insertion machine BLE With the BLE, the workpieces are glued and dowelled on the front. Optional the BLE can be upgraded with a drilling unit, counter milling unit and longitudinal stop will. A 10" touch panel allows easy operation for manual or online operation. Base frame: in a compact design, covered with sheet metal Table support approx. 800 x 200 mm position 1 ---------------------- 1 glue station full jet valve Glue quantity precisely adjustable Glue gun for counter hole gluing position 2 ---------------------- 1 stainless steel glue pump, high-pressure pump and glue hose item 3 ---------------------- 1 press-in station with dowel separation and press-in cylinder item 4 ---------------------- 1 oscillating conveyor for dowels d 8 x 50 mm with feed hose into the injection unit item 5 ---------------------- 1 processing unit with cross table, linear guide and 3NC axis motors X = 200 mm processing width Y = 120 mm processing height Z = 50 mm offset item 6 ---------------------- 1 positioning controller Touch panel 10" color 500 drilling patterns can be created and saved, which can be easily accessed when needed (1 drilling pattern can have up to 16 dowel positions) Software prepared for ONLINE connection With online control, the data for the control must be provided by the software be prepared. Our machine can then read and process this data. --------------------------------------------------------- Total price in this version Pos. 1 to Pos. 6: on request! Options with additional prices: ---------------------- item 7 ---------------------- 1 horizontal drilling unit, 1,000 W drilling motor Speed ??4,000 - 8,000 rpm, collet holder Pneumatic drill feed Surcharge: EUR 4,305.00 Additional accessories such as a larger touch screen, additional dowel station for additional dowel sizes or scanner for Program selection on request! Prices net plus statutory VAT, without packaging/shipping and without Installation. (technical data according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5924 · Boring and dowel inserting machine

STEMA - Spinamatic GLF/HP -Video- - - neu -

Technical details

SPINAMATIC mod. GLF-HP Dübeleintreibgerät mit Leimangabe für Fensterfertigung ---------------------------------------------------------------- komplett wie folgt : - Fahrbare Ausführung - Dübelzuführung zur Pistole wird durch SPS-Steuerung gesteuert. - 1 Wendelförderer zur Aufnahme von Dübeln mit 1 Zuführung - Leimanlage ist mit Hoch-Druckpumpe 10:1 und Sonderleimspritzdüse für Dickleim (Typ D3 oder D4-Einkomponent) augerüstet - pneumatische Pistole für Dickleim- und Dübeleinsetzen mit Ausrüstungen für nur einen Dübeldurchmesser nach Wahl zwischen : 6 - 8 – 10 oder 12 mm. Dübellänge : min. 25 mm. – max. 60 mm. Tiefeinsetzen = 30 mm. Der Leim wird durch eine Sonderleimspritzdüse, die mit SPS-Steuerung für elektronische Dosierung in Verbindung ist, gespritzt . - Flexibler Arm mit Gegengewicht zum Aufhängen der Pistole . - Die Maschine stimmt mit den Vorschriften europäischer Richtlinien überein . BETRIEBSDATEN: Einfasig 220 VOLT - 50 HZ. Leistung 0,7 Kw Druckluft 6 ATM vertrocknet Luftverbrauch 1,5 NL / zyklus (technische Angaben laut Hersteller - ohe Gewähr!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6480 · Boring and dowel inserting machine

PIZZI - Leimangabe f. Duebelbohrungen - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6349 · Boring and dowel inserting machine

GÖTZINGER - PowerDrill m. Duebeleintreiben - - neu -

Technical details

Götzinger Power Drill in special version with dübelleim and press-in station With the Götzinger PowerDrill, you can choose: - Drill the front and long sides - Doweling of doors, seatings, fighters - The drilling patterns are freely programmable - You can: Grip handle and corner bearing, with quick-change Multi-spindle drilling heads - You can: lock casings, pusher and PZ as well as 3D tapes and drill - The machine has a horizontal and a vertical milling unit - A simple control lets you create drilling and milling programs, Save and recall POWER DRILL - drilling and milling machine Universal drilling machine for drilling olives, corner bearings, dowel work On the front and the front, milling, lock boxes, tapes, etc. Base in stable design, covered with sheet metal Table top 1800 x 200 mm Processing unit: X-axis - 500 mm working travel Y-axis - 100 mm Z axis - 105 mm 1 drilling unit horizontal (dowel drilling unit left) Drilling motor 380 V, 1,100 W Clamping chuck d = 8/10 4,000 - 11,000 rpm can be adjusted 1 drilling unit vertically from above - fixed Drilling motor 1.1 KW, 3,000 rpm Quick change of the drill head 1 drill head BKF 2/3, quick-changeable, (corner bearing) On the loose part, hardware according to customer requirements including drill replacement Control: electro-pneumatic with three axes NC positioning controller and integrated machine function Input via TFT display, 10 "color Machine complete, CE compliant, with 1 set of drilling tools Dübo je 1xd = 6,8,10,14 + 2 Roughing cutter d = 16, 1 milling cutter d = 20, ready for connection 1 drill head BKF 3, fast exchangeable for olives including drill bit Fitting according to customer requirements 2 drilling units 1 x horizontal for drilling from above (for tapes) 1 x vertical for dowel work, right Drilling motor 1.100 Watt, infinitely variable 4,000 - 11,000 rpm with collet chuck ER 20 2 Milling units for lock boxes 1 x horizontal for tapes, lock boxes 1 x vertically from above for PZ, pushers, tapes Milling motor 2.2 KW Speed ??adjustable 3,000 - 16,000 rpm Clamping tool holder ER 25 1 length stop right and left, working length 2.8 m NC-controlled When the length stop is used, the fixed stops are removed. Dimension: LxBxH = 2.50 x 1.50 x 2.20 m - Weight machine 850 kg PowerDrill LxBxH = 0,30 x 0,30 x 6,00 m - Weight length stop 100 kg 1 Dübelleim- and press-in station consisting of: - Swing conveyor for dowels with feed -Dübeleinpressstation -High pressure glue pump made of stainless steel with glue container - Full jet valve for precise glue application Exhaust nozzle Price for 1 dowel diameter The basic machine will be about 300 mm longer (Technical data according to manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6450 · Boring and dowel inserting machine

GÖTZINGER - PowerDrill Typ BF 315 -Video- - - neu -

Technical details

Götzinger Power Drill Type BF 297 With the Götzinger PowerDrill you can, depending on the type and design: Griffoliven drill on the loose frame part or for finished wings, with multi-spindle drilling head, quick-change, also for milling of the lock case for WK 2 or intermediate gear Ecklager drill on loose frame part, with Mehrspindelbohrkopf, quick-change, corner-oriented over stop or custom made (tilt window) Drill vertically from above for fitting, pre-drill for clip on loose frame part Milling vertically from above for pushers, profile cylinders, 3-D hinges Horizontal drilling with 2 drilling units, different drilling diameters, Dowel drill front and long side, plywood / fighter, sprouts, Corner connection, front door etc. Milling horizontally for lock case / fitting etc. machine description Base frame in stable welded construction, linear guide for the X-axis Table top 3,000 x 200 mm 6 clamping cylinder pneumatic with auto. Ausweichhub 2 side stops for machining on the front side, manually swiveling in and out 2 longitudinal stops can be manually swiveled in and out Travel: X-axis - 3,000 mm working length Y-axis - 120 mm Z-axis - 105 mm Aggregate: 1 drilling unit (unit 1) vertically from above, drill motor 1,1 KW Speed ??1,500 - 12,000 rpm, 1 spindle, collet holder ER 20 1 Bohraggreagt (unit 2) vertically from above, drill motor 1,1 KW Speed ??3,000 rpm, with drill head quick change device 1 boring head BKF 3, olives, quick-change 1 boring head BKF 3/2 corner bearing, quick-change 1 milling unit (Agg.3) vertically from above, milling motor 2 KW, 1,500 - 16,000 rpm, collet holder ER 25 2 horizontal drilling units (Agg.4 and 5) 1.0 KW, 1.500 - 12.000 U / min, Collet holder ER 20 1 milling unit horizontal (Agg.3) 2.0 KW, 1.500 - 16.000U / min, Collet holder ER 20 Electro-pneumatic control with 3-axis control X, Y, Z NC positioning controller make B + R input via TFT display 10 " Machine complete with 1 set of drilling tools dm 6, 8, 10 and 12, 2 roughing carbide cutters HM dm 16, CE compliant, ready for connection Suction connection: 1 x dm 120 Power connection: 1 x 400 V, 16 amps Air connection: 1 x LW 9 mm OPTION: Longitudinal stops right / left with NC axis high / low programmatically, thus dimension input by folding / light measure possible, Dimension: LxWxH = 4.80 x 1.60 x 2.40 m - weight machine 1,500 kg (technical data according to manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6529 · Boring and dowel inserting machine

GÖTZINGER - Power Drill -300 Video - - - neu -

Technical details

1 NEW drilling and milling center Götzinger Power Drill 300 With the Götzinger PowerDrill you can, depending on the type and design: - Drill on the front and on the long side - Dowels of front doors, pegs, fighters - The drilling patterns are freely programmable - You can drill: handle slides and corner bearings, with quick-change multiple spindle - You can: Milling lock case, pusher and PZ as well as 3D belts and drill - The machine has a horizontal and a vertical milling unit - A simple control lets you create drilling and milling programs, save and call again Base frame in sturdy design, covered with sheet metal Table top 1800 x 200 mm Processing unit: X-axis - 500 mm working travel Y-axis - 0-120 mm Z-axis - 0-105 mm (above table) Horizontal aggregates: 1 horizontal drilling unit (dowel drilling unit left) -------------------------- Drilling motor 220 V, 1.1 kW Collet holder ER 25 4,000 - 11,000 rpm adjustable 1 milling unit horizontal for lock case -------------------------- Milling motor 2.2 kW Speed ??controllable 3,000 - 16,000 rpm Collet holder ER 25 1 horizontal drilling unit (dowel drilling unit right) -------------------------- Drilling motor 1100 W, infinitely variable 4,000 - 11,000 rpm, with collet holder ER 25 Vertical aggregates: 1 drilling unit vertical -------------------------- Drilling motor 1100 W, infinitely variable 4,000 - 11,000 rpm, with collet holder ER 25 1 boring unit vertical - with quick-change boring head -------------------------- Drilling motor 1,1 KW, 3,000 rpm Included: 1 boring head BKF 2/3, for corner bearing incl. Drill set, quick-change -------------------------- On loose item, drill assembly to customer fitting 1 boring head BKF 3, for olive incl. Drill set, quick-change -------------------------- On loose item, drill 1 cubo d = 25, 2 x dowel d = 10 1 milling unit vertical for lock case -------------------------- Milling motor 2.2 kW Speed ??controllable 3,000 - 16,000 rpm Collet holder ER 25 1 piece length stop right and left, usable length 2.7 m, NC controlled Control: electro-pneumatic with three-axis NC positioning controller and integrated machine function Input via TFT display, 10 "color Machine complete, CE-compliant, with 1 set of drilling tools, DÜBO each 1 x d = 6,8,10,12 + 2 roughing cutters d = 16, ready for connection Loading dimensions: Machine L x W x H = 2.50 x 1.50 x 2.30 m, weight 850 kg Length stop L x W x H = 6.00 x 0.30 x 0.30 m, weight 100 kg ------------------------------ Total price in above mentioned version, ex works: on request Plus freight and installation / instruction (Technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6838 · Boring and dowel inserting machine

GÖTZINGER - PowerDrill - - gebraucht -

Technical details

1 Götzinger Power Drill drilling and milling center ------------------------------------------------- Machine is FACTORY TESTED by Götzinger before delivery. Depending on the type and version, you can use the Götzinger PowerDrill to: - Drill on the front and long sides - Doweling of house doors, timbers, brackets - The drilling patterns are freely programmable - You can: drill handle olives and corner bearings, with quick-change ones Multi-spindle drilling heads - You can: mill lock cases, handles and PZ as well as 3D hinges drill - The machine has a horizontal and a vertical milling unit - A simple control allows you to create drilling and milling programs, save and access again and again Stable base frame, covered with sheet metal Table support 1800 x 200 mm Processing unit: X-axis – 500 mm useful travel Y axis – 0-120mm Z axis – 0-105 mm (above table) Horizontal aggregates: 1 horizontal drilling unit (dowel drilling unit on the left) -------------------------- Drill motor 1,100 W with collet holder 4,000 – 11,000 rpm continuously adjustable 1 horizontal milling unit for lock case -------------------------- Milling motor 2.2 kW Speed adjustable 3,000 - 16,000 rpm Collet holder ER 25 1 horizontal drilling unit (dowel drilling unit on the right) -------------------------- Drill motor 1,100 W with collet holder 4,000 – 11,000 rpm continuously adjustable Vertical aggregates: 1 vertical drilling unit -------------------------- Drill motor 1100 W, continuously adjustable 4,000 - 11,000 rpm, with collet holder ER 25 1 vertical drilling unit - with drill head quick-change device -------------------------- Drill motor 1.1 KW, 3,000 rpm Included: 1 drill head BKF 2/3, for corner bearings including drill set, quick-change -------------------------- On a loose item (fittings on request!) 1 drill head BKF 3, for olive, including drill set, quick-change -------------------------- On the loose item 1 vertical milling unit for lock case -------------------------- Milling motor 2.2 kW Speed adjustable 3,000 - 16,000 rpm Collet holder ER 25 1 piece of length stop right and left, usable length 3 m right/3 m left, NC controlled Control: electro-pneumatic with three axes NC positioning controller and integrated machine function Input via 10 inch touch panel Machine complete, CE compliant, with existing tools Loading dimensions: Machine L x W x H = 2.50 x 1.50 x 2.30 m, weight 850 kg Length stop L x W x H = 6.00 x 0.30 x 0.30 m, weight 100 kg -------------------------------- Total price in the above version, ex warehouse Oberkochen Pictures/video archive, show the same machine type (no original pictures available yet). (Technical information according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

TOP Manufacturer:

RUCHSER -