Coil Line

Machinelist: Coil Line

Coil Line

- EnTeHa GmbH & Co.KG

- Im Wollenklingen 6

- 69517 Gorxheimertal

- Deutschland

-

+49 6201 2630 545

-

info@enteha.de

www.enteha.de

#2081-0843 · Coil Line

IRON / RDI Group - CRM-20 - - unbekannt -

Technical details

Coil - Durchlauf / Blechvorschub Drive: 2,2

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-60165 · Coil Line

HS-AUTOMATION - MS 4000 / MR 58 - - 2009 -

Technical details

Decoiler type MS 4000 - Hydraulic spreading - Hydraulic pressure roller from above - Swivel-in limit roller at the front, contact disc at the rear - Auxiliary drive - Reel movable - Coil lifting table Straightening machine type MR 58 Rollers hardened and ground. - Pneumatically ventilated feed roller - Straightening rollers adjustable as a block - Lateral belt guidance at the inlet - Hydraulic band insertion aid - Straightening head can be opened - Large roll basket and transfer table at the outlet - Ultrasonic transmitter for loop control - Swivel control panel - Control Siemens S7

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-60174 · Coil Line

ARKU - AH 3000/2/250/ST / RM 3025.4/2 - - 2004 -

Technical details

Decoiler AH 3000/2/250/ST with continuously variable drive, hydraulic central spread, Automatic post-spreading system, hydraulic pressure device, hydraulic swivel, Straightening machine RM 3025.4/21 with continuously variable drive, driven straightening rollers, manual Roller mill adjustment, quick-change device for the straightening rollers Belt loop control via ultrasound Material thickness / with material width 3.80 / 250 mm Material thickness / with material width 6.00 / 100 mm

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-60157 · Coil Line

DREHER - 1676D-FQ/2380 D-FPS - - 1999/97/2012 Umbau -

Technical details

Control conversion to SIEMENS S7 in 2012 - pneumatic pressure roller on the side - pneumatically ventilated feed roller - Straightening rollers manually adjustable - lateral belt guide at the inlet - Large roller basket at the outlet - Ultrasonic transmitter for loop control - Roller feed type 1125 D - Bandwidth max. 510 mm - Band thickness max. 6 mm with full width 5.50 mm - Roll diameter 125mm - Feed speed: max. 100 m/min. - pneumatically ventilated top roller - Lateral tape guide with digital display - Inlet roller basket

- Maschinen Schwartpaul GmbH

- Am Wasserwerk 1

- 58840 Plettenberg

- Deutschland

-

+49 (0)2391-95960

+49 (0)2391-959620 -

info@maschinen-schwartpaul.de

www.maschinen-schwartpaul.de

#2020-15438 · Coil Line

AMT - AHR 1,5 - - 1999 -

Technical details

Datasheet

Request / Contact

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-60167 · Coil Line

KOHLER - 30.400/9-2000.2H - - 1995 -

Technical details

- straightening machine type KRE 30.400/9 with infinitely variable drive, motoric adjustment of the roller cassette, rapid clamping device - double decoiler type 2000.2 H with pneumatic lag brake, hydraulic expansion, hydraulic snubber roll - coil loop control via ultrasound

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-60173 · Coil Line

COVEMA/SCHWABE - VRMA32/96-MHM 2 - - 1994 -

Technical details

COVEMA-SCHWABE belt system consisting of: Reel MHM 2 - hydraulic expansion (motor 1.5kW/1500 U) - hydraulic pressure roller - with drive Feed leveling machine VRMA 32/96 The straightening head can be opened using hydraulics Intermediate ventilation with operating instructions with control panel

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-60163 · Coil Line

KOHLER - 18.260.19-1000.2 - - 1991/2023CHECK -

Technical details

- Speed control ultrasonic via belt loop - Digital measuring device - Motorized roller mill adjustment - Drive motor 8 kW - Hydraulic reel expansion - Pneumatic reel brake - Quick change device for the straightening rollers and support rollers - SIEMENS S5 control - Press inlet height 1200-1400 mm - Electrical plans in the control cabinet - Instruction manual available Dimensions: - Straightener with reel 3.00 x 1.80 x 2.10 m - Tape guide 1.50 x 0.50 x 1.40 m - Control cabinet 0.90 x 0.60 x 2.10 m The system is energized and can be tested with material.

- Pressen HAAS GmbH

- Kreuzsteig 6

- 72479 Straßberg

- Deutschland

-

+49 7574 59 97 59

+49 7574 92 17 24 -

info@pressen-haas.de

www.pressen-haas.de

#2053-0346 · Coil Line

WANZKE - HRS 500/2500 - - 1990 -

Technical details

- Ambold Pressen GmbH

- Sommeritzer Straße 43

- 04626 Schmölln

- Deutschland

-

+49 (0)3449183314

+49 (0)3449123492 -

info@ambold-pressen.de

www.ambold-pressen.de

#1010-633 · Coil Line

KOHLER - 150.2/150.1 - - 1989 -

Technical details

-Coil rewinding system with 3 single coils decoiler, type 150.2: -Spool width: 140mm -Spreading: manual bolt spreading -Spool outer diameter: 800 mm -Brake: disc brake pneu. -Side shift: manually via spindle winding reel, type 150.1: -Brake: engine brake -Side shift: manual via spindle

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-60159 · Coil Line

KOHLER - 10 120 - 300.2 - - 1979 -

Technical details

- Reel and straightener as a combination with a common frame - Manually adjustable reel brake - Coil limiting ring at the front, fixed washer at the rear - Reel can be moved manually laterally - manual reel spreading - side belt – guide rollers with central adjustment at the inlet - manual block adjustment of the straightening mechanism, display via dial gauges - Oil - central lubrication - Loop control via sensor - Speed adjustable via potentiometer - Manually adjustable hold-down roller at the inlet - Large roller basket with cover on the outlet - Free-standing control panel - Lateral adjustment of the reel using a hand crank

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-60158 · Coil Line

KOHLER - 12 120 -150.2 - - 1979 -

Technical details

- Reel and straightener as a combination with a common frame - Manually adjustable reel brake - Coil limiting ring at the front, fixed washer at the rear - Reel can be moved manually laterally - manual reel spreading - side belt – guide rollers with central adjustment at the inlet - manual block adjustment of the straightening mechanism, display via dial gauges - Oil - central lubrication - Loop control via sensor - Speed adjustable via potentiometer - Belt support at the outlet - Free-standing control panel - Lateral adjustment of the reel using a hand crank - Belt support at the outlet

Plate Shear - Mechanical

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08037 · Plate Shear - Mechanical

KAPEMA - SMP 20-20 - - Fabrikneu / new -

Technical details

The new motor guillotine type SMP is a well dimensioned machine with all-welded link guides. The drive takes place with a Standard geared brake motor via a chain connection to the main axle. the Knives are of the highest quality. The optimal cutting angle secures the Together with the rubber-covered blank holder perfect cuts. Bearings and guides are maintenance and lubrication-free. Standard equipment: • Back gauge 665 with mm scale. • cutting edge lighting. • Section counter. • Table extensions 600 mm. • Right angle stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • Rear protective grille, warranty = 12 months for single-shift operation. Other models: 1275 x 3mm, 1250 x 4mm, 2050 x 2mm Machine dealer with own stock of 1600 m².

Datasheet

Request / Contact

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08408 · Plate Shear - Mechanical

KAPEMA - SMP 12-30 - - Fabrikneu / new -

Technical details

The guillotine shears type SMP is a well-dimensioned machine with all-welded gate guides. The drive takes place with a standard geared brake motor via a chain connection to the main axis. The knives are of the highest quality. The optimal cutting angle ensures together with the rubber-coated sheet metal holder, perfect cuts. Bearings and guides are maintenance-free and lubrication-free. Standard equipment: • Back gauge 635 with mm scale. • Cutting line lighting. • Section counter. • Table extensions 600 mm. • Right-angled stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • rear photocell. Pre-freight to our stock + packaging 270, -. Machine dealer with own stock of 1600 m².

Datasheet

Request / Contact

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08417 · Plate Shear - Mechanical

KAPEMA - SMP 20-30 - - Fabrikneu / new -

Technical details

The new motor guillotine type SMP is a well dimensioned machine with all-welded link guides. The drive takes place with a Standard geared brake motor via a chain connection to the main axle. the Knives are of the highest quality. The optimal cutting angle secures the Together with the rubber-covered blank holder perfect cuts. Bearings and guides are maintenance and lubrication-free. Standard equipment: • Back gauge 665 with mm scale. • cutting edge lighting. • Section counter. • Table extensions 600 mm. • Right angle stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • Rear protective grille, warranty = 12 months for single-shift operation. Other models: 1275 x 3mm, 1250 x 4mm, 2050 x 2mm Machine dealer with own stock of 1600 m².

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-01210 · Plate Shear - Mechanical

RFR - MS/24 - - ca. 1960 -

Technical details

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-22062 · Plate Shear - Mechanical

RAS - 53.60 - - 380/6 -

Technical details

Datasheet

Request / Contact

- SKM Industriemaschinen

- Röntgenstr. 3

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 954 986 0

+49 (0) 7309 954 986 1 -

info@skm-maschinen.de

www.skm-maschinen.de

#2032-1144 · Plate Shear - Mechanical

OSTAS - RGM 1550 x 3 - - 2019 -

Technical details

Producer: OSTAS Type: RGM 1050 x 3 YOM: new Max. Shearing Length: 1.050 mm Shearing Capacity: 3 mm Shearing Angle: 2°30' Strokes Per Minute: 35 d/d Motor Power: 3 kW Table Width: 510 mm Table Height: 820 mm Rear Gauge Distance: 500 mm Dimensions of the machine (LxWxH): 1.640 x 2.060 x 1.210 mm Weight: ca. 1.100 kg Additional information: • Manual backgauge with 500 mm stroke • Squaring arm with T-slot, stopper and ruler • Foot pedal • Front sheet holding arms • Cutting line lighting • Protection Cages optional: • Cutting unit counter • Motorised backgauge with 500 mm stroke • Backgauge with NC control • Pneumatic Sheet Support System • Optical security bar • 0-180° angle cutting

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-3320042 · Plate Shear - Mechanical

METALLKRAFT - FTBS 1050-10 - - 2017 -

Technical details

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-94086 · Plate Shear - Mechanical

DURMA - MS 2504 - - 2012 -

Technical details

** Current new price with special accessories ~ 33.000 euros ** from a maintenance workshop / good condition (!!) Furnishing: - robust / powerful mechanical guillotine shears - electric backgauge, with ball screws - with DURMA NC control - model D-Touch 7 * Control unit with touchscreen function * 128 MB internal memory (programming possible) * Multilingual (English, Turkish, German) * INCH/metric conversion - manual cutting gap adjustment, from the front * analogue display of the material thickness - 1x extra long side stop 2.000 mm, with support foot & T-slot - 2x support arms - Ball casters in the support table - free-moving footswitch - rear protective device (light barrier) - original operating instructions (machine + control) Special accessories included : - Pneumatic sheet metal holding device, for thin sheet metal blanks - 1x extra long side stop, with support foot - 1x box with spare knife

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9325259 · Plate Shear - Mechanical

DURMA - MS 2504 - - 2012 -

Technical details

** Current new price with special accessories ~ 33.000 euros ** from a maintenance workshop / good condition (!!) Furnishing: - robust / powerful mechanical guillotine shears - electric backgauge, with ball screws - with DURMA NC control - model D-Touch 7 * Control unit with touchscreen function * 128 MB internal memory (programming possible) * Multilingual (English, Turkish, German) * INCH/metric conversion - manual cutting gap adjustment, from the front * analogue display of the material thickness - 1x extra long side stop 2.000 mm, with support foot & T-slot - 2x support arms - Ball casters in the support table - free-moving footswitch - rear protective device (light barrier) - original operating instructions (machine + control) Special accessories included : - Pneumatic sheet metal holding device, for thin sheet metal blanks - 1x extra long side stop, with support foot - 1x box with spare knife

Datasheet

Request / Contact

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9325336 · Plate Shear - Mechanical

HM - NWKS 2000/3 - - 2010 - DIGI

Technical details

** Machine from a maintenance workshop ** maintained condition (!!) Furnishing: - robust electro-mechanical sheet metal shears - Machine body in a closed design as an all-steel welded construction - heavy / robust drive motor (5.5 KW) - electro-motorized backgauge, including digital control unit * Adjustment range max. 1.000 mm * Input of target / actual value possible - manual cutting gap adjustment, adjustable from the front - 1x table side stop - Ball rollers in the support table - 1x freely movable foot switch, including EMERGENCY stop button - front finger protection - original instruction manual * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9325336

Datasheet

Request / Contact

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

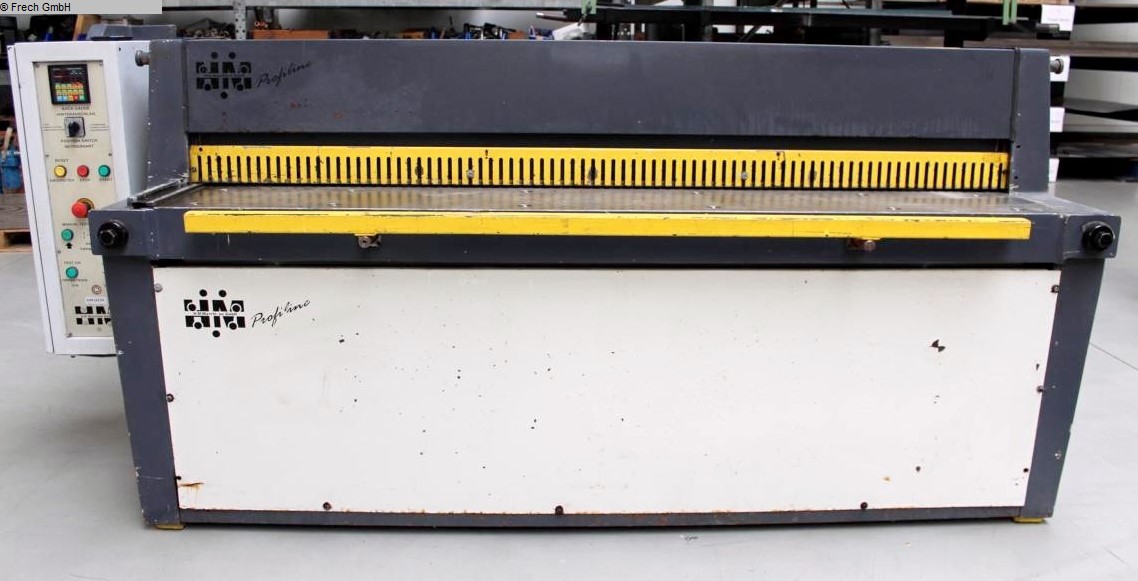

#1073-94181 · Plate Shear - Mechanical

HM - NWKS 2000/3 - - 2010 - DIGI

Technical details

** Machine from a maintenance workshop ** maintained condition (!!) Furnishing: - robust electro-mechanical sheet metal shears - Machine body in a closed design as an all-steel welded construction - heavy / robust drive motor (5.5 KW) - electro-motorized backgauge, including digital control unit * Adjustment range max. 1.000 mm * Input of target / actual value possible - manual cutting gap adjustment, adjustable from the front - 1x table side stop - Ball rollers in the support table - 1x freely movable foot switch, including EMERGENCY stop button - front finger protection - original instruction manual

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-94167 · Plate Shear - Mechanical

SCHRÖDER - MHSU 1500/2,0 - - 2009 -

Technical details

- manual back gauge 500mm - Hold-down device with hard rubber strip - Sheet metal holding device mechanically controlled to the rear including sheet metal slide - Rear area protection via light barrier