Bevel Gear Generator - Straight

Machinelist: Bevel Gear Generator - Straight

Bevel Gear Generator - Spiral

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24006 · Bevel Gear Generator - Spiral

HURTH-MODUL - KF 250 B - - 1998 - Siemens Sinumerik 840 C

Technical details

incl. suction

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-16040 · Bevel Gear Generator - Spiral

KLINGELNBERG - KNC 25 P - - 1997 -

Technical details

max. wheel diameter mm gear width mm max. module 6 min. module 1.5 max. workpiece diameter 275 mm tooth width max. 5.5 mm spiral angle 0 - 60 ° number of teeth 5 - 120 transmission ratio min. 1:1 transmission ratio max. 1:10 milling drive motor 20 kW workpiece drive 14.5 kW total power requirement 62 kVA weight of the machine ca. 12 t dimensions of the machine ca. 4,7 x 4,387 x 2,45 m Tool spindle (D-axis) - workpiece spindle speed (infinitely) 60 to 350 [...] Tool positioning axis (E-axis) - swivel range 0 to 360° - swivel speed max. 19.5°/s Workpiece spindle (B-axis) - mounting diameter outer cone (1: 4) 140 mm - standard internal cone (1:20) 99.218 mm - workpiece spindle speed max. 300 [...] - workpiece spindle passage 90 mm Workpiece positioning axis (Y-axis) - travel 870 mm - speed max. 4.5 m/min Roller rotation axis (A-axis) - swivel range 315° - swivel speed max. 40°/s Axis intersection (Z-axis) - travel range max. +/- 50 mm - speed max. 0.657 m/min Workpiece swivel axis (C-axis) - swivel range -8.5 to 98° - swivel speed max. 21.5 °/s Milling depth axis (X-axis) - travel from -25 to 640 mm - max. speed 6 m/min Machinen distance (V-axis) - travel 150 mm - speed max. 1.6 m/min

Datasheet

Request / Contact

- Leyendecker & Hollmann GmbH

- Giesenheide 18

- 40724 Hilden

- Deutschland

-

+49 (2103) 28097-0

+49 (2103) 28097-99 -

info@LHmachine.com

www.LHmachine.com

#1083-02478 · Bevel Gear Generator - Spiral

KLINGELNBERG - KNC 25 P - - 1997 -

Technical details

Tool spindle (D-axis) - workpiece spindle speed (infinitely) 60 to 350 r.p.m. Tool positioning axis (E-axis) - swivel range 0 to 360° - swivel speed max. 19.5°/s Workpiece spindle (B-axis) - mounting diameter outer cone (1: 4) 140 mm - standard internal cone (1:20) 99.218 mm - workpiece spindle speed max. 300 r.p.m. - workpiece spindle passage 90 mm Workpiece positioning axis (Y-axis) - travel 870 mm - speed max. 4.5 m/min Roller rotation axis (A-axis) - swivel range 315° - swivel speed max. 40°/s Axis intersection (Z-axis) - travel range max. +/- 50 mm - speed max. 0.657 m/min Workpiece swivel axis (C-axis) - swivel range -8.5 to 98° - swivel speed max. 21.5 °/s Milling depth axis (X-axis) - travel from -25 to 640 mm - max. speed 6 m/min Machinen distance (V-axis) - travel 150 mm - speed max. 1.6 m/min - 13 milling cutters included -

36.000 €

Datasheet

Request / Contact

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

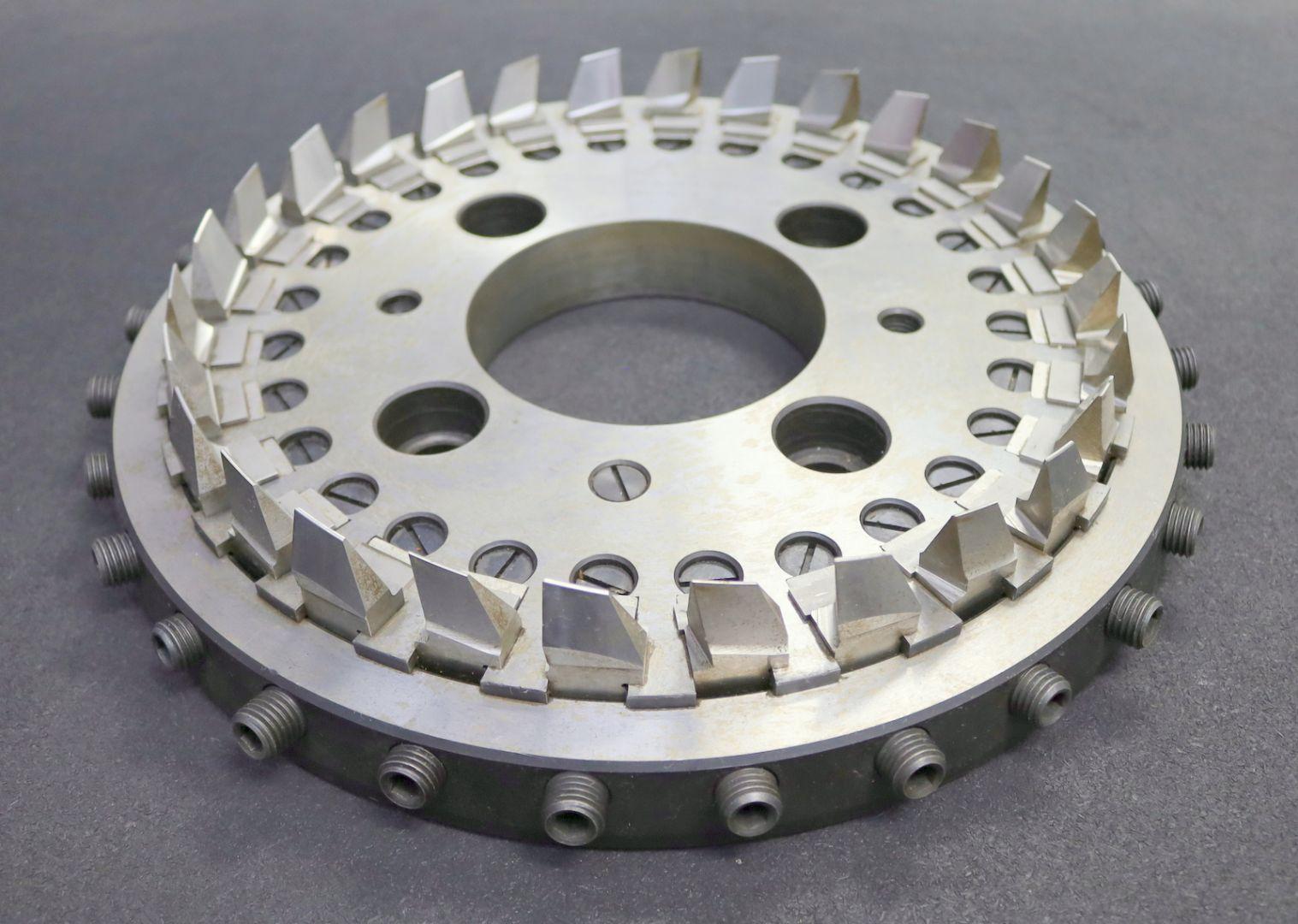

#1139-00446 · Bevel Gear Generator - Spiral

WMW-MODUL - MK 12 - - - konventionell

Technical details

WMW MODULE Arcoid cutter head MK 12" 2§m - 304.8 for bevel gears with tapered tooth height analog Gleason for bevel gear milling machine MODUL ZFTKK 500 28 knife inserts 05M VESTA WORKS 552 A-311 AJ/ck 30499005 used weight 29.4kg We have 4 different types in stock. You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.

Bevel Gear Generator - Straight

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20211 · Bevel Gear Generator - Straight

GLEASON - 104 CONIFLEX - - 1997 - Fanuc 0-GC

Technical details

- CNC Control Fanuc 0-GC - Set of Change Gears For Speed, Feed and Roll, Index and Ratio Roll - Hydraulic Double-Acting Chucking Mechanism (Less Draw-in-Bar and Nut) - Self-Contained Hydraulic System - Self-Contained Coolant System - Workhead Brake - Full Guards Cover - Full Compliment of Electrics (Motor/Controls) SPECIFICATIONS: Cone Distance: 0 to 4-1/2" Pitch Angle: 84 deg. 18 min. (max); 5 deg. 42 min. (min) Extreme Ratio: 10-to-1 Pitch Diameter: 10-to-1 ratio; 8-1/2" (max) Pitch Diameter: 1-to-1 ratio; 6" (max) Diametral Pitch (coarsest): 3 DP Diametral Pitch (finest): 20 DP Face Width: 1-3/8" (max) Index Range: 9 to 93 inclusive, and most numbers up to 175 Pressure Angles: 20, 22-1/2 & 25 deg. Diameter of Taper Hole at Large : 3-29/32" Taper per Foot: 39/64" Depth of Taper: 6" Diameter of Hole Through: 2-7/16" Spindle Nose to Machine Center: 1-1/2" to 9" Cutter Speeds: 98 to 286 (feet per minute) Feeds: 4.2 to 69.2 (seconds per tooth)

Datasheet

Request / Contact

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19248 · Bevel Gear Generator - Straight

MODUL - ZFTK 500/2 - - 1988 -

Technical details

change gears coolant Chip Conveyor

Datasheet

Request / Contact

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-07681 · Bevel Gear Generator - Straight

KLINGELNBERG - BF 204 - - 1980 -

Technical details

Segmental Gear Generating Machine - specifically for rational production of tapered or cylindrical segmental gears, such as steering sector shafts. This model also operates to the generating-indexing method and permits tooth thickness modifications on the centre Tooth. with chip conveyor and handbooks ex works South Americ

Datasheet

Request / Contact

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-00397 · Bevel Gear Generator - Straight

KLINGELNBERG - - - - konventionell

Technical details

KLINGELNBERG Palloid gear hobs We have around 450 milling cutters in stock in the module range from 1-7. Manufacturer KLINGELNBERG Please contact us! You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.

TOP Manufacturer:

KLINGELNBERG - GLEASON - MODUL -